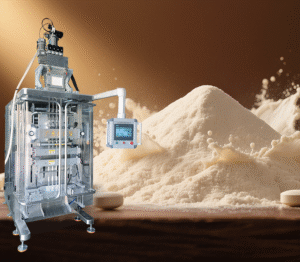

What Defines the Optimal Stick Packing Machine for Powder Supplements?

For the dynamic market of nutritional powders—including protein, vitamins, and probiotics—single-serve stick packs have become the preferred packaging format. This choice is driven by their portability, ease of use (direct pouring), and reduced material footprint. Selecting the right machine is critical, involving balancing speed, accuracy, sanitation, and long-term operational costs. As experienced manufacturers in the packaging machinery sector, we understand these core challenges.

Prioritize Precision: The Necessity of Servo Auger Fillers

When evaluating any stick packing machine, the filling system is the most crucial component. For powdery products, especially non-free-flowing food supplement powders like fine protein or collagen, a Servo Motor Driven Auger Filler is the standard for high quality and reliability. This choice directly reflects the Experience and Expertise required in high-stakes food production.

Achieving High Accuracy and Compliance

A high-quality auger system guarantees outstanding filling precision, often achieving $\pm0.1\text{g}$ or better. This precision is non-negotiable for ensuring the correct dosage of active ingredients, which is vital for product compliance and establishing Trust with consumers. The positive displacement of the screw mechanism ensures stable, uniform measurement, regardless of the powder’s flow characteristics. This superior control reduces the risk of expensive overfilling, improving your operational ROI significantly.

Capacity Planning: The Efficiency of Multi-Lane Systems

In a competitive landscape, production speed is paramount. For medium to large-scale operations, investing in a multi-lane stick packing machine is mandatory. This choice demonstrates market Authority and operational scalability.

A state-of-the-art multi-lane stick packing machine typically features independently controlled servo sealing and cutting systems. It can operate at speeds up to 45 cycles per minute, delivering hundreds of packs per minute across multiple lanes (e.g., 6 to 12). This high-speed capability dramatically lowers the cost per unit, making your food supplement powder stick pack packaging machines highly efficient. For more technical details on enhancing speed, you may consult external industry bodies like PMMI for their latest technical papers.

Hygienic Design: Building Trust Through Sanitation

The food and nutraceutical industries demand the highest standards of hygiene. Your stick packing machine design and materials must comply with international regulations to build consumer Trust.

Key Elements for Compliance (Trustworthiness)

Product-contact parts must be constructed from SS304 or SS316 stainless steel, adhering to GMP and FDA guidelines. The machine must feature an easy-to-clean, no-dead-angle design. For sensitive powders like probiotics, the food stick pack packaging machines must offer Nitrogen Flushing capability. This feature purges oxygen before sealing, significantly extending the shelf life and integrity of your product. Furthermore, the machine should be fully compatible with advanced multi-layer barrier films (e.g., PET/AL/PE) necessary to provide superior moisture and light protection.

Choosing the Format: Stick Pack vs. Sachet in the Packaging Market

When navigating the broader stick and sachet packing machine market, the choice between the narrow stick pack and the flat sachet often comes down to consumer usage. The stick pack is highly advantageous for powder supplements aimed at “on-the-go” consumption because of its shape and superior pouring experience, making it easier to dispense the contents directly into a water bottle.

The stick pack also uses approximately 30-40% less film material than a standard sachet for the same volume, offering a more sustainable and cost-effective solution. To explore how this can optimize your current line, you can review our internal resources on vertical form fill seal (VFFS) technologies and their application to different formats. This strategic choice ultimately boosts your brand’s perceived convenience and value.