In today’s fast-paced manufacturing environment, a cartoning machine is essential for efficient, accurate packaging of cartons in industries ranging from food and pharmaceuticals to cosmetics and hardware. This guide dives into the core technology, key machine types, industry applications, and buying considerations—helping factory owners, procurement managers, automation leads, OEM/ODM partners, and packaging engineers make informed decisions.

What Is a Cartoning Machine?

A cartoning machine automates the process of erecting cartons, inserting products, and sealing the cartons for shipment. By replacing manual tasks, it boosts throughput, ensures consistency, and reduces labor costs. Common synonymous terms include:

Cartoning box packing machine

Auto cartoning machine

Cartoning packing machine

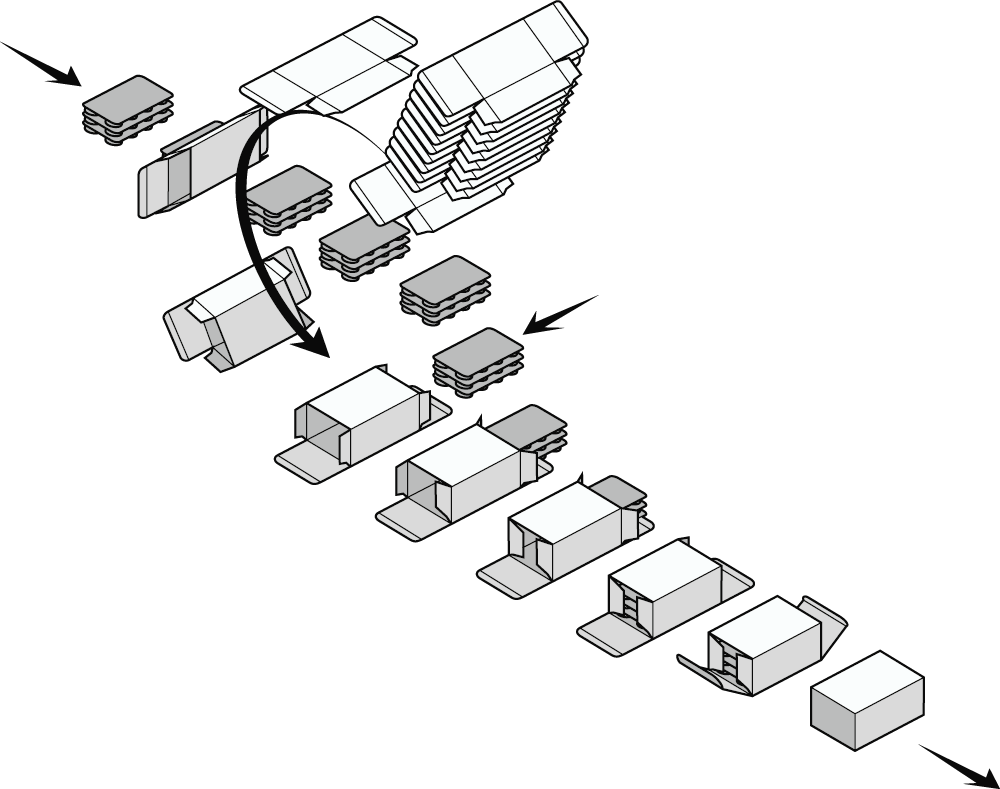

Key Components & Working Principle

Most cartoning systems share these core elements:

Carton Magazine & Feeder: Stores flat carton blanks and feeds them one by one.

Carton Erector: Forms and locks the carton into its open shape.

Product Insertion Station: Precisely places items—bottles, sachets, tubes—into cartons.

Carton Sealer: Folds flaps and applies glue or tape for closure.

Control System: PLC-driven interface for adjusting speed, timing, and diagnostics.

The cycle repeats continuously or intermittently, depending on whether you choose a continuous motion cartoning machine or an intermittent cartoning machine.

Types of Cartoning Machines

Automatic Cartoning Machine

Fully automatic systems handle erecting, product insertion, and sealing without manual intervention. Ideal for high-speed lines, they achieve up to hundreds of cartons per minute with minimal error.

Horizontal Cartoning Machine

Products enter the carton from the side—perfect for bottles, vials, or blisters. Also known as automatic horizontal cartoning machine, it excels in sectors requiring delicate handling, such as pharmaceutical cartoning machine lines .

Continuous vs Intermittent Cartoning Machine

Continuous Cartoning Machine: No stop between cartons; best for ultra-high-speed needs, like high speed cartoning machine setups.

Intermittent Cartoning Machine: Stops briefly for product insertion—more common for diverse product shapes and mid-range speeds.

Industry Application

Food Cartoning Machine

From snack boxes to ice cream cartons, food grade cartoning machines ensure hygienic, rapid packaging. Case in point: a bakery using a high speed cartoning machine to pack biscuits at 200 carts/min.

Pharmaceutical Cartoning Machine

Stringent regulations demand precision. Pharmaceutical cartoning machines for ampoules, vials, and oral liquids guarantee tamper-evident packaging and accurate insertion .

Cosmetic Cartoning Machine

Cosmetic OEMs rely on cosmetic cartoning machine solutions for products like lipstick, lotion, and facial masks—integrating delicate product handling with breakout detection.

Specialized Cartoning Solutions

Bottle Cartoning Machine: Handles round-neck bottles—ideal for wine bottling lines.

Toothpaste Cartoning Machine: Supports soft tubes with intermittent motion.

Pouch Cartoning Machine & Sachet Cartoning Machine: Adaptable for flexible packaging formats.

Benefits of Investing in a Cartoning Machine

Enhanced Productivity

Speeds up packaging by 2–5× versus manual operations.

Consistent Quality

Uniform flap folding and sealing reduce rework.

Cost Savings

Lower labor costs and material waste.

Flexibility

Easy changeovers for multiple SKUs—from tube cartoning machines to bar cartoning machines.

Scalability

Modular designs let you upgrade from semi-automatic to continuous motion cartoning machine as demand grows.

How to Choose the Right Cartoning Machine

When evaluating options, consider:

Factor Recommendation Production Speed ≥ required cartons/minute (e.g., 60–200 cpm) Product Type Bottle, pouch, tube, sachet, etc. Carton Size Range Min/max dimensions supported Motion Mode Continuous vs intermittent Integration Needs With upstream line (filler, labeling) Regulatory Compliance FDA/ISO standards for food/pharma Changeover Simplicity Tool-less format parts After-sales Support Local service network & parts availability For in-depth specs and machine models, visit our Burgenmachine Cartoning Machines.

Why Choose Burgenmachine

As a leading cartoning machine manufacturer, Burgenmachine offers:

Customized Solutions: From ice cream cartoning machines to hardware cartoning machine factory setups.

Global Support: Technical service in your region for speedy maintenance.

Innovation & Reliability: Patented sealing heads and intelligent fault diagnostics.

Call to Action

Ready to revolutionize your packaging line with a high-performance cartoning machine?

👉 Request a Quote | 📧 packing@bgpacking.com | 📞 +86 18344408617

Unlock greater efficiency, consistency, and scalability—partner with Burgenmachine today!

2 Comments

Each paragraph feels like a step along a thoughtful path, leading to places I never knew existed within myself.

Thank you for your feedback! We’re glad you found the article engaging. If you’d like to explore more practical insights on choosing the right cartoning machine for your production line, feel free to check out our related guides or contact us for tailored solutions.