When food companies evaluate stick packing machines, the main concern is: which type offers the best balance between speed, accuracy, and cost efficiency? Since output is determined largely by the number of lanes, manufacturers must carefully compare single-lane, multi-lane, and custom setups. In this guide, we’ll break down 7 stick pack machine types by capacity, their best-fit product categories, and how to maximize ROI.

What Are Stick Packing Machines?

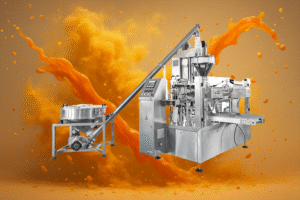

Stick packing machines are automated vertical form-fill-seal systems that create slim sachets for powders, liquids, and mixes. They are popular in the food, beverage, nutraceutical, and pharmaceutical industries because stick packs

Use less film than traditional pouches (eco-friendly advantage)

Are lightweight, portable, and travel-friendly

Ensure accurate portion control for powders and liquids

Enhance branding and shelf appeal with sleek design

According to PMMI research, single-serve formats like stick packs are among the fastest-growing packaging styles in food and nutraceutical markets.

Why Food Manufacturers Need Stick Packing Machines

Adopting stick packing machines provides food manufacturers with multiple benefits:

Precise dosing — accuracy within ±0.1 g for powders or drip-free filling for liquids

Labor savings — one machine can replace 6–10 manual workers

Scalability — multi-lane designs reach up to 1,200 sticks/min

Product safety — sealed packaging prevents contamination

Market competitiveness — slim sachets boost customer convenience

From instant coffee in Asia to vitamin powders in Europe, stick packs are shaping the way global brands deliver products.

7 Best Value Stick Packing Machine Types (By Output Capacity)

Output: 20–60 sticks/min

Best for: Startups, pilot production, small-batch R&D runs

Products: spice powders, test-batch instant coffee, small-scale honey sachets

Highlights: Low cost, compact footprint, easiest to operate and maintain.

2. 2-Lane Stick Pack Machine

Output: 80–120 sticks/min

Best for: SMEs moving from manual to semi-automatic

Products: sugar sticks, nutraceutical powders, flavored drink sachets

Highlights: Doubles productivity vs. single-lane; still affordable for growing companies.

3. 4-Lane Stick Pack Machine

Output: 160–240 sticks/min

Best for: Food factories supplying supermarkets or regional wholesalers

Products: instant coffee powder, electrolyte sachets, collagen powders

Highlights: Balanced speed and investment; suitable for medium-scale production.

4. 6-Lane Stick Pack Machine

Output: 300–480 sticks/min

Best for: Mid-sized factories with multiple SKUs

Products: vitamins, energy gels, ketchup sachets

Highlights: Strong ROI from high throughput; reduced reliance on manual packaging.

5. 8-Lane Stick Pack Machine

Output: 480–720 sticks/min

Best for: Large manufacturers and co-packers

Products: 2-in-1 coffee mixes, zero-sugar sweeteners, instant beverage powders

Highlights: High speed + consistency; excellent for FMCG brands scaling globally.

6. 10-Lane Stick Pack Machine

Output: 600–960 sticks/min

Best for: Export-oriented production facilities

Products: milk powders, isotonic drinks, pharmaceutical powders

Highlights: Handles long production runs efficiently; supports global demand.

7. Custom Multi-Lane Configurations (12+ Lanes)

Output: 1,200+ sticks/min

Best for: Multinational food groups, contract manufacturers

Products: fortified nutrition powders, high-volume instant coffee, condiments

Highlights: Tailored dosing (dual auger or piston), nitrogen flushing, eco-film compatibility, full integration into packaging lines.

Matching Machines to Product Types

Choosing the right stick packing machines depends heavily on what you’re packing:

Powder products (protein powders, coffee, supplements): Best suited for 2–10 lane powder stick pack packaging machines, depending on production scale.

Liquid products (honey, sauces, condiments, gels): Typically handled by single to 6-lane liquid stick pack machines for higher dosing accuracy.

Mixes (2-in-1 or 3-in-1 instant coffee, blended powders): Require 6–8 lane machines with dual-dosing or triple-dosing augers.

High-value nutraceuticals (collagen, probiotics, vitamins): Often packed on fewer lanes (1–4) to ensure product protection and minimize waste.

👉 Not sure which lane configuration suits your product best? Talk to Burgen Machine’s experts — our team can analyze your product characteristics and suggest the most cost-effective solution tailored to your factory needs.

How to Choose the Right Stick Packing Machine

When making an investment, consider these factors:

Product type — liquids need piston fillers, powders need auger fillers.

Desired output — estimate sachets/day or sachets/minute to size the machine.

Accuracy requirements — powders often demand ±0.1 g accuracy; liquids require drip-free nozzles.

Budget and ROI — single-lane machines cost less but scale slower; multi-lane models shorten payback period.

Special packaging features — nitrogen flushing for coffee, easy-tear notches for retail powders, coding for compliance.

Many buyers underestimate the ROI timeline. A well-matched stick pack machine can often pay for itself within 6–12 months due to reduced labor costs and increased output.

👉 Need a ROI calculation for your specific product? Request a free consultation with Burgen Machine here and get a customized cost-benefit analysis.

How to Use and Maintain Stick Packing Machines

Getting the most from your investment requires proper operation and preventive care:

Calibrate dosing systems for each new product batch to maintain consistency.

Run trial batches before full-scale production to catch errors early.

Adjust sealing bars depending on film type (laminated, recyclable, eco-friendly).

Clean dosing units (auger or piston) after each run to avoid product residue.

Schedule preventive maintenance — lubrication, replacement of wear parts, and sensor checks.

Following these steps minimizes downtime and maximizes machine lifespan. Many of Burgen Machine’s global clients adopt quarterly service schedules, which reduce unexpected stoppages by up to 40%.

👉 Want to establish a maintenance plan tailored to your factory? Consult Burgen Machine engineers — we provide both technical training and after-sales service packages to keep your production line running at peak efficiency.

FAQs About Stick Packing Machines

Q1. Which stick pack machine is best for sauces?

A liquid stick pack machine with piston filler, typically single to 4 lanes, ensures drip-free operation.

Q2. How much does a stick packing machine cost?

Entry-level single-lane starts at ~$15,000; multi-lane custom systems can exceed $60,000.

Q3. Can one machine pack both coffee and supplements?

Some models are versatile, but dedicated machines improve accuracy and efficiency.

Q4. What industries use stick packs?

Food, nutraceuticals, pharma, and beverages all rely on stick packs for single-serve convenience.

Q5. Are stick packs eco-friendly?

Yes. They use less film than traditional pouches, and newer models support recyclable films.

For food manufacturers, stick packing machines are a critical investment. Whether you choose a single-lane liquid stick pack machine for small-batch sauces or an 8-lane powder stick pack packaging machine for instant coffee and supplements, the right choice balances output, cost, and product type.

👉 Ready to explore your options? Contact our team to get expert advice and a tailored solution for your production line.