Meet the demands of today’s high-speed beverage, nutraceutical and cosmetic markets with our advanced Liquid Stick Pack Packaging Machine. Engineered to:

Crush Capacity Limits: 2/4/6/8/12 parallel lanes deliver up to 600 packs per minute, eliminating order backlogs.

Guarantee Filling Accuracy: Servo-driven piston pumps with real-time weight feedback ensure ±0.5% dosing precision, even for varying viscosities.

Minimize Downtime: Integrated CIP/SIP cleaning cycles finish in under 10 minutes — switch recipes seamlessly.

Ensure Leak-Proof Seals: Dual-mode hot-seal & ultrasonic sealing locks in freshness without drips or spills.

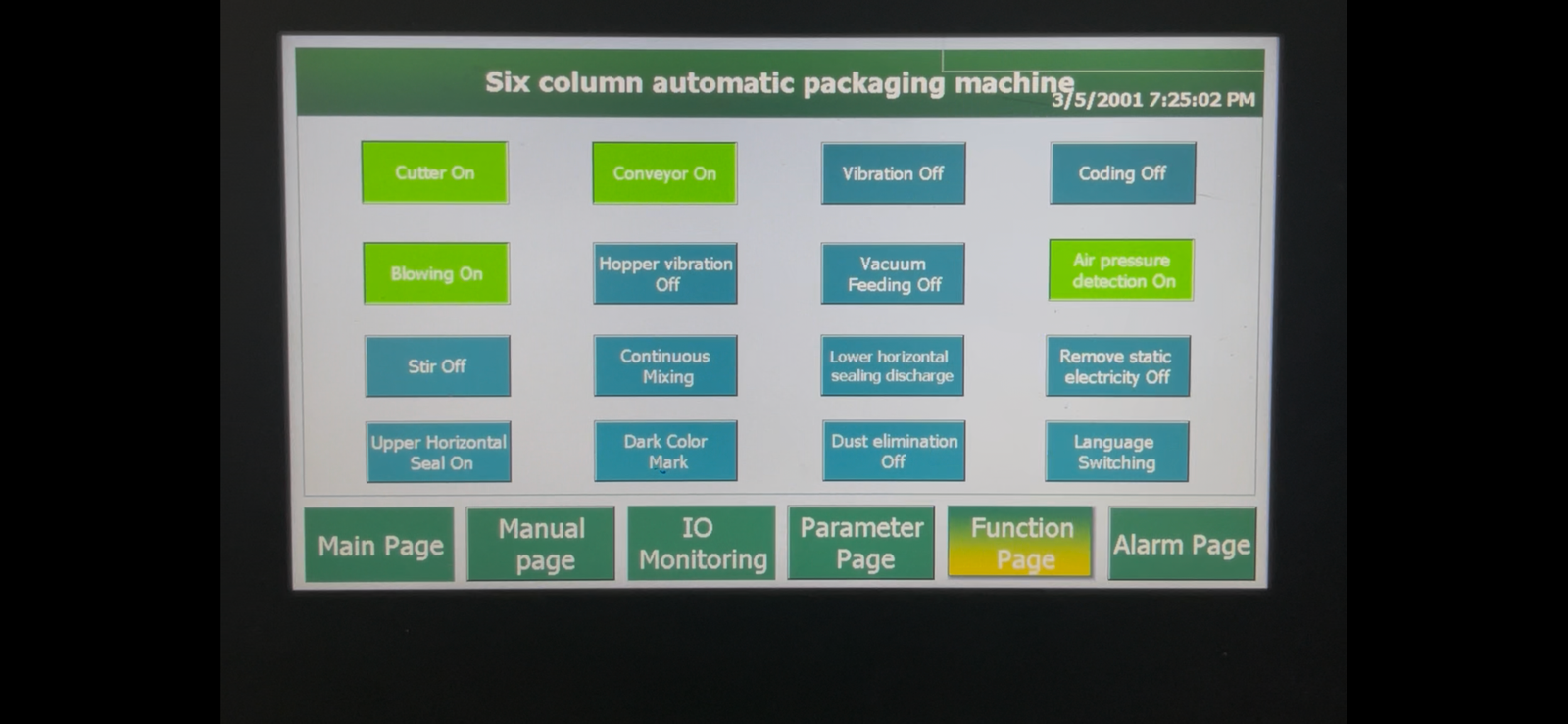

Simplify Operation: PLC + HMI one-touch recipe changes and remote diagnostics keep your line running 24/7.

Empower your production line with automation that pays for itself — faster ROI, fewer rejects, and total peace of mind.

Experience the power of our Liquid Stick Pack Machine firsthand in this one-minute demo video. See all key features in motion — from the 12-lane servo filling heads achieving 400 packs/min, to the seamless hot-seal + ultrasonic sealing that locks in liquid without leaks. Observe the rapid CIP/SIP cleaning cycle kicking in and a one-touch HMI recipe change mid-run, proving how effortless it is to switch products. Whether you’re in beverages, nutraceuticals, cosmetics or beyond, this video shows why our machine delivers unmatched productivity and reliability.

Achieve unmatched throughput with up to 400 packs per minute across 12 parallel lanes.

Ensure leak-proof pouches with combined hot-seal and ultrasonic-seal.

Complete internal wash cycles in under 10 minutes to maximize uptime.

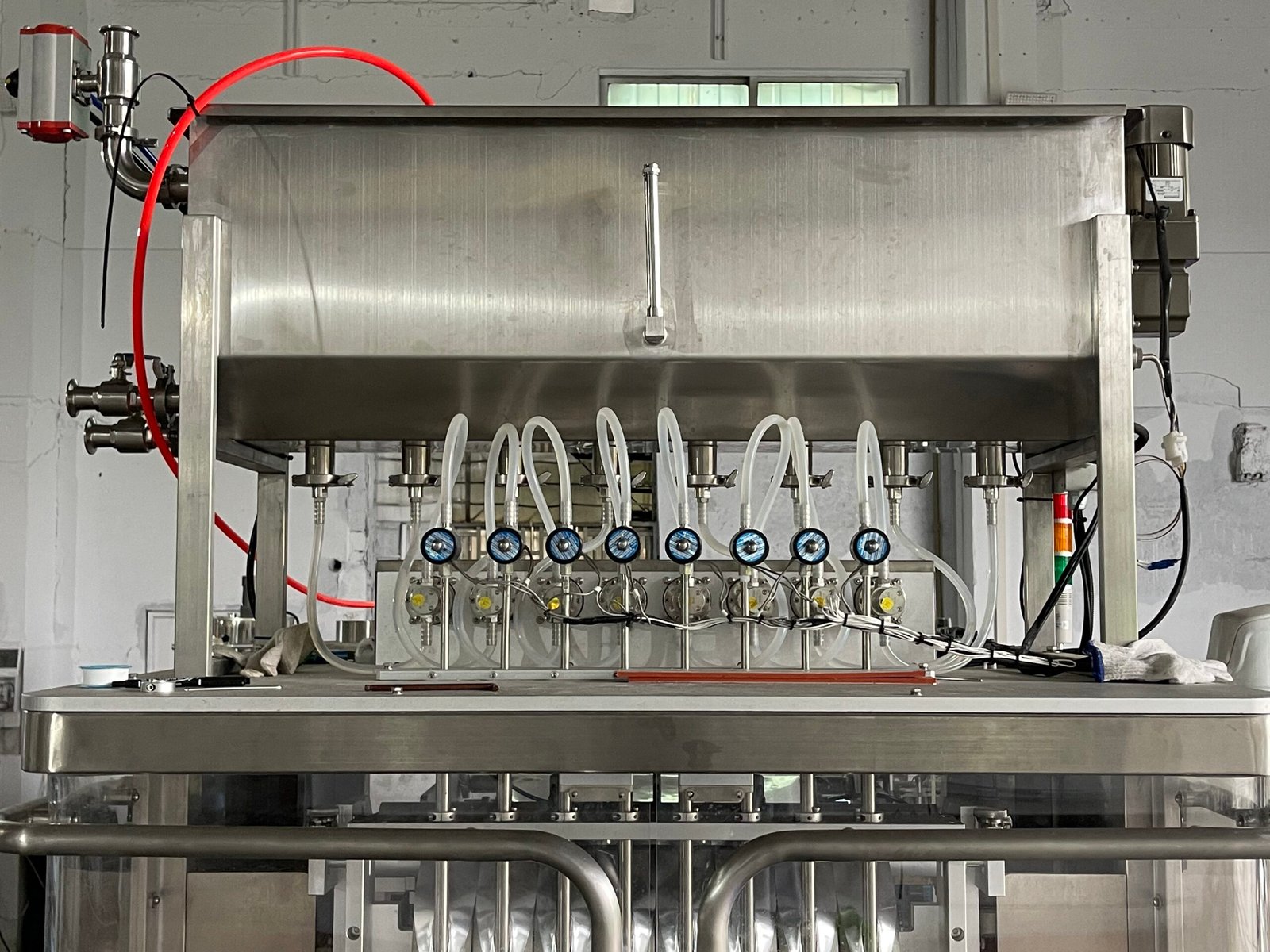

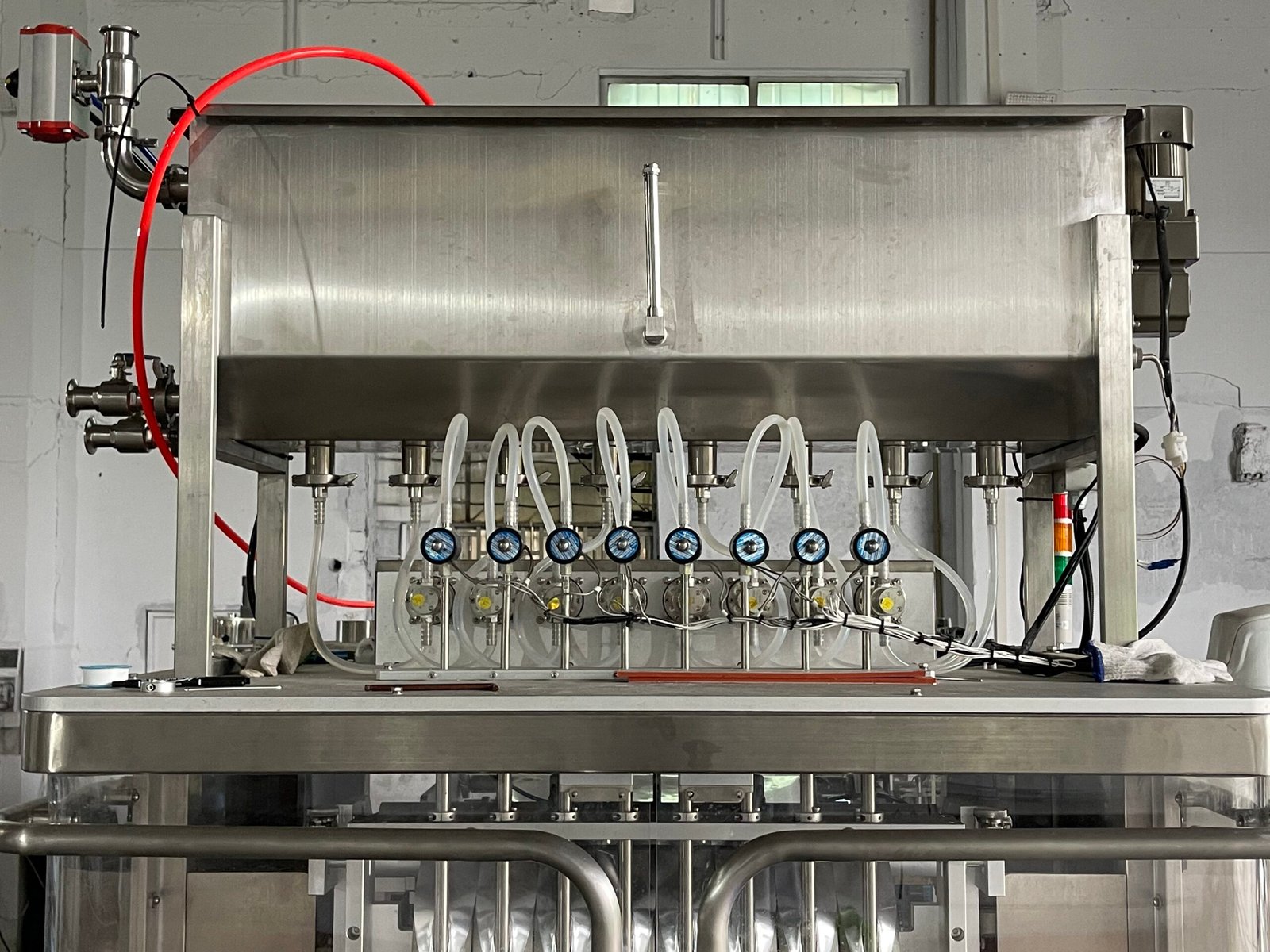

Select from ceramic, syringe or peristaltic pumps—each integrated with real-time weight feedback to guarantee dosing accuracy of ±0.5%.

Operate in your preferred language and switch between pre-configured pouch recipes at the touch of a button. Our intuitive HMI supports up to 10 languages and stores optimized settings for each pouch type, so you can change bag formats in seconds—no manual reprogramming required.

Explore our suite of liquid packaging systems designed for every scale and application. Click “Learn More” to dive into detailed specifications and see which solution fits your production goals.

A versatile solution for high-speed bottle, vial, and container filling. Choose from servo-driven piston, ceramic, syringe or peristaltic pumps to suit viscosities from water to syrup. Fully integrated CIP/SIP cleaning ensures rapid changeover and minimal downtime.

Specialized for premade spout, zipper and stand-up pouches. Fast pouch feeding and precise spout insertion coupled with ultrasonic sealing guarantee leak-proof, user-friendly packs. Ideal for liquid soaps, hand sanitizers and ready-to-drink beverages.

Our single-lane Liquid Sachet Packing Machine delivers up to 100 packs per minute with ±0.5% dosing accuracy—perfect for small-to-medium runs of stick and sachet formats. Equipped with dual hot-seal & ultrasonic sealing, it guarantees leak-proof sachets. Tear-notch pouches ensure effortless one-hand opening. Seamless CIP cleaning and HMI-driven recipe recall minimize downtime and simplify changeovers, making it ideal for specialty batches, pilot runs, and flexible production lines.

Hear directly from our clients in the food, pharmaceutical, and chemical sectors about how the Powder Sachet Packing Machine improved their throughput, ensured consistent product quality, and minimized material waste.

Since upgrading to the 12-lane Liquid Stick Pack Machine, our production jumped from 150 to 400 packs per minute. We’ve virtually eliminated order backlogs and cut labor costs by 30%.

cut labor costs

The seamless CIP/SIP cleaning and one-touch recipe changes reduced our downtime from 2 hours to under 10 minutes per batch. Our facility now runs three shifts non-stop.

Saved in Operational Costs

With dual hot-seal + ultrasonic sealing, we achieved zero leakage on high-viscosity serums. Fill accuracy within ±0.5% has slashed our product waste by 25%

slashed our product waste by

Here are six of the most common questions about our powder stick packing machine—answered to help you make an informed decision.

Our multi-lane model can reach up to 1200 packs per minute, while the single-lane sachet variant delivers up to 100 packs per minute.

All pump options (ceramic, syringe, peristaltic) integrate real-time weight feedback to ensure ±0.5% dosing accuracy, regardless of liquid viscosity.

The automated CIP/SIP system completes a full internal wash in under 10 minutes, minimizing downtime between batches.

Yes—our multi-language HMI stores preset recipes for all common pouch formats (three-side, four-side, round-corner, tear-notch). One-touch switching loads the correct fill volume, seal parameters, and speed in seconds.

Regular checks of pump tubing and sealing modules are recommended every 1,000 operating hours. Quick-change pump heads and seal modules simplify replacements. Annual full-system inspections by our technicians ensure optimal performance.

Absolutely. We provide 24/7 remote diagnostics, on-site installation & commissioning, and comprehensive operator training in your local language. Spare parts are stocked regionally for fast delivery.