Choosing the right stick packing machine is a strategic decision for any food manufacturer aiming to improve efficiency, consistency, and scalability. Whether your production line handles instant coffee, powdered drinks, liquid supplements, or energy gels, the wrong equipment choice can lead to downtime, inconsistent quality, and regulatory risks.

This guide explains what food manufacturers should look for when selecting an automatic stick packing machine, using a clear, structured, and practical approach that aligns with how buyers actually evaluate equipment.

Why Choosing the Right Stick Packing Machine Matters in Food Manufacturing

A modern food production line demands more than just speed. A reliable stick packing machine must meet food safety standards, handle different product characteristics, and remain stable under continuous operation.

Food manufacturers typically package:

powders (coffee, sugar, drink mixes)

liquids (vitamins, syrups, supplements)

gels (isotonic energy gels)

Each product type places unique demands on the machine.

1. Product Type Compatibility Is the First Priority

Before comparing speeds or prices, define what you will package.

Powder Products

If you package:

instant coffee

drink powders

nutritional blends

You need a powder stick packing machine with an auger dosing system for accuracy and stability.

Liquid & Gel Products

For:

liquid food supplement stick pack packaging machines

isotonic energy gel stick pack packaging machines

You need piston pumps or peristaltic dosing systems with leak-proof sealing.

2. Dosing Accuracy & Consistency

Food brands rely on precise formulation.

A high-quality stick packing machine should offer:

±1–2% dosing accuracy

Stable performance across long shifts

Minimal powder leakage or liquid dripping

This is especially critical for 3-in-1 instant coffee mix stick pack packaging machines, where ingredient ratios affect taste.

3. Lane Configuration & Production Capacity

Different food manufacturers require different output levels.

| Lane Option | Suitable For |

|---|---|

| 1–2 lanes | Small batches / testing |

| 3–4 lanes | Medium-scale food factories |

| 6–12 lanes | High-volume production |

Choosing the right number of lanes avoids overinvestment while ensuring scalability.

4. Food Safety & Hygiene Design

A food-grade stick packing machine must meet strict hygiene requirements.

Look for:

SUS304 / SUS316 stainless steel contact parts

Smooth surfaces without dead corners

Easy-to-disassemble filling components

Dust collection systems for powders

This is mandatory for coffee stick pack packaging machines and supplement products.

5. Sealing Quality & Package Integrity

Stick packs must survive transportation and shelf storage.

A reliable machine provides:

Uniform longitudinal and cross seals

Adjustable sealing temperature

Strong seals without film burning

Poor sealing leads to leaks, contamination, and customer complaints.

6. Flexibility for Multiple SKUs

Most food manufacturers do not produce just one product.

A flexible stick packing machine should support:

Different stick lengths and widths

Multiple recipes stored in the PLC

Fast changeover between products

This is essential if you produce both powder stick packing machine applications and liquid or gel products.

7. Automation & Control System

Automation improves consistency and reduces labor dependence.

Key features to look for:

PLC + touchscreen HMI

Recipe memory

Automatic fault detection

Production data tracking

These features help food manufacturers maintain stable output and quality control.

8. Integration with Upstream & Downstream Equipment

An automatic stick packing machine should integrate smoothly into your production line.

Common integrations include:

automatic feeders

check weighers

counting systems

cartoning machines

This is especially important for manufacturers planning future expansion.

9. After-Sales Support & Manufacturer Reliability

Even the best machine needs support.

Choose suppliers that offer:

Remote technical assistance

Fast spare parts availability

Long-term service commitment

Proven export experience

Machine reliability depends heavily on the manufacturer’s engineering and service capabilities.

Application-Specific Considerations

For Coffee & Instant Drink Producers

Machines must support:

nitrogen flushing

aroma protection

fine powder handling

Especially relevant for 3-in-1 instant coffee mix stick pack packaging machines and coffee stick pack packaging machines.

For Supplements & Functional Foods

Precision dosing and hygiene are critical for liquid food supplement stick pack packaging machines.

For Sports Nutrition Brands

Machines handling gels require stable filling and anti-leak sealing, making them suitable for isotonic energy gel stick pack packaging machines.

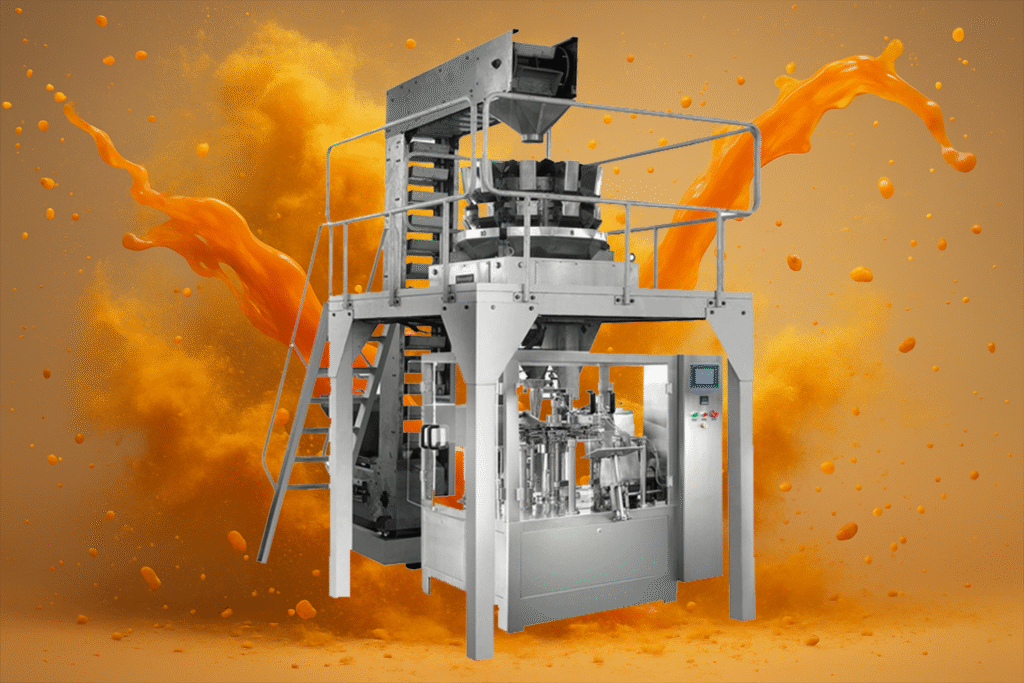

Why BURGEN Machine Is a Reliable Choice for Food Manufacturers

BURGEN Machine designs and manufactures automatic stick packing machines specifically for food, beverage, and supplement production lines.

✔ Why food manufacturers choose BURGEN:

15+ years of stick pack machine expertise

Powder, liquid, and gel packaging solutions

Food-grade stainless steel construction

Stable dosing and sealing systems

Exported to 50+ countries

Professional English-speaking support team

BURGEN machines are widely used for:

powder stick packing machine solutions

coffee stick pack packaging machines

liquid food supplement stick pack packaging machines

isotonic energy gel stick pack packaging machines

Where to Learn More & Get Expert Advice

If you are planning or upgrading a food manufacturing line, exploring detailed machine configurations is the best next step.

👉 Learn more about powder stick packing machines:

https://burgenmachine.com/stick-packing-machine/powder-stick-packing-machines/

👉 Explore nutraceutical & food supplement stick pack solutions:

https://burgenmachine.com/pack-solution-nutraceutical-stick-pack-packaging-solution/

📩 Contact BURGEN Machine for a tailored recommendation.

Share your product type, production target, and packaging format — we’ll help you select the right stick packing machine for your food manufacturing line.