Liquid products such as honey, sauces, oral liquids, and nutritional drinks present unique packaging challenges: they can easily leak if sealing is not strong, require precise dosing to avoid waste, and vary in viscosity from watery solutions to thick gels. Many manufacturers struggle with high labor costs, inconsistent sealing, and downtime caused by complex cleaning.

Our Liquid Sachet Packing Machine is built to solve these problems. With advanced sealing technology, flexible pump systems, and fully automated operation, it guarantees leak-proof sachets, consistent product quality, and maximum efficiency. Whether you are in the food industry, nutraceutical production, pharmaceutical filling, or personal care packaging, this machine ensures your products are packed safely, attractively, and at scale — all while complying with GMP and CE standards

High-strength heat sealing technology prevents leakage even with viscous liquids like honey or shampoo. Supports 3-side seal, 4-side seal, and stick formats.

Multiple pump options (gear, piston, peristaltic) guarantee accurate dosing for both watery and thick liquids.

Supports different sachet styles and sizes to meet marketing and branding needs (single-serve, travel packs, sample sachets).

Reduced labor costs, minimized product waste, and improved efficiency ensure a faster return on investment

Watch how our liquid sachet packing machine handles everything from film unwinding to precise liquid filling and leak-proof sealing. This real-time demo shows the efficiency, accuracy, and consistency you can expect in your production line

The film roll is automatically fed into the machine, maintaining stable tension and alignment for consistent sachet formation

The film is shaped into sachets by precision forming molds, ensuring uniform sizes for 3-side, 4-side, or stick sachets.

Liquid is dosed with high accuracy using pumps (gear, piston, or peristaltic), adapted for both low and high-viscosity products.

High-strength sealing bars apply heat and pressure, ensuring airtight, leak-proof seals for every sachet.

Sachets are cut into individual packs or strip formats, then discharged onto the output conveyor for secondary packaging.

To maximize efficiency, our Liquid Sachet Packing Machine can be integrated with downstream equipment for secondary packaging and production line automation. From liquid filling to cartoning, we provide a complete packaging solution.

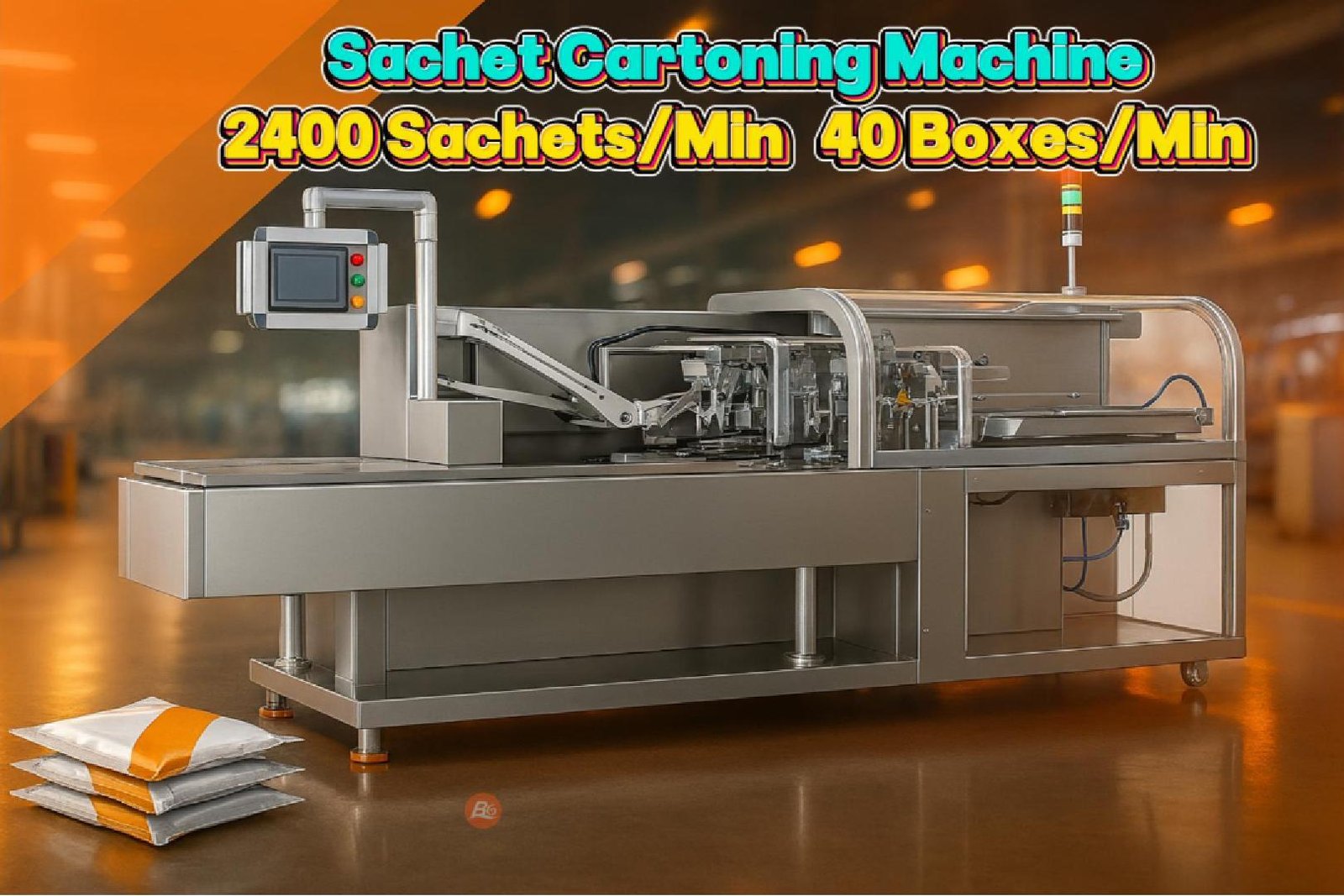

Automatically packs finished sachets into cartons for retail and distribution. Suitable for food, pharma, and nutraceutical industries.

Features

High-speed cartoning for sachets and stick packs

Compact design, easy line integration

Custom carton sizes for branding

Ideal for bottles, jars, or tubes. Handles low- to high-viscosity liquids with precision dosing.

Features

Suitable for water, oils, syrups, gels

PLC controlled for high accuracy

Easy cleaning with CIP system

Specialized for liquid stick packs, widely used in health supplements, energy gels, and daily-use liquids

Features

Multi-lane options (2–12 lanes) for mass production

Perfect portion control for single-serve products

High-speed output, small footprint

We introduced Burgen’s liquid sachet packing machine into our collagen drink production line last year. The machine has significantly improved our efficiency — production speed increased by 45%, and dosing accuracy is consistently within ±1%. Our operators appreciate the user-friendly interface and recipe storage system, which saves time during product changeovers. Most importantly, our customers are impressed with the attractive, leak-proof packaging, which has boosted our brand reputation.

speed increased

For years we struggled with honey sachet packaging — most machines couldn’t handle the viscosity without causing leakage or inconsistent filling. Burgen’s liquid sachet packing machine solved this issue completely. The piston pump system ensures precise filling even for thick honey, and the strong sealing technology guarantees zero leakage. Our sales team also reported higher demand from retailers who prefer single-serve sachets. This machine has allowed us to scale up production without increasing labor costs.

Saved in Operational Costs

As a pharmaceutical manufacturer, compliance with GMP standards is critical. Burgen’s liquid sachet packing machine exceeded our expectations. The stainless steel design, CIP cleaning system, and validation-friendly structure made regulatory approval smooth and efficient. In addition, the machine’s accuracy ensures that every sachet of oral solution meets dosing standards, minimizing waste and ensuring patient safety. Our QA team is very satisfied, and we are now planning to expand the line with a second unit.

Increase in Company Revenue

A liquid sachet packing machine is a fully automated system designed to form, fill, and seal small sachets containing liquid products. It works by unwinding film, forming sachets, dosing liquid with precision pumps, and sealing them leak-proof. Unlike stick pack machines, which produce narrow tubes, sachet liquid packing machines typically make wider sachets with three-side or four-side seals, offering more branding space and flexible filling volumes. These machines are widely used in food, pharma, and cosmetics industries, packaging items like honey, ketchup, syrups, lotions, and oral solutions. BURGEN machines are built with SS316L contact parts, ensuring hygiene and ±1% dosing accuracy.

👉 For tailored advice, WhatsApp us at +86 183 4440 8617 or fill out the form.

The benefits of a liquid sachet packing machine extend beyond efficiency. It allows manufacturers to achieve accurate dosing, leak-proof sealing, and hygienic operation. Compared with manual or semi-automatic systems, it reduces labor costs and ensures consistency. Sachet liquid packing machines also save packaging material due to their compact size while offering convenient single-use portions for consumers. For high-viscosity products like honey or syrups, BURGEN provides specialized honey sachet packing machines with anti-drip nozzles and reinforced sealing systems. Overall, businesses benefit from faster production speeds, lower wastage, and improved market competitiveness.

👉 Discover your ROI today: WhatsApp +86 183 4440 8617 or fill out the form.

Industries that rely heavily on sachet liquid packing machines include:

Food & Beverage: honey sachet packing machines for portioned honey, ketchup sachets, sauces, soy sauce, dressings.

Pharmaceuticals: oral rehydration salts, liquid syrups, single-dose medications.

Cosmetics: lotion, shampoo sachets, facial essence, travel-size liquids.

Each sector values portability, hygiene, and accurate dosing. For example, pharmaceutical companies require compliance with GMP, while food producers focus on extended shelf life and consumer convenience. BURGEN’s liquid sachet packing machines offer all-in-one solutions, helping brands expand globally with versatile and reliable packaging.

👉 To explore applications in your industry, WhatsApp +86 183 4440 8617 or submit the form

In pharmaceuticals, liquid sachet packing machines guarantee precise dosing and compliance with GMP and FDA standards. For food and beverage companies, they extend shelf life with nitrogen flushing and strong seals, while offering convenient portion control. In cosmetics, they enable attractive travel-size sachets and samples for marketing. BURGEN combines these industry-specific benefits, ensuring each machine adapts to your product needs—whether it’s an oral solution, honey sachet, or facial serum.

👉 For sector-specific solutions, WhatsApp +86 183 4440 8617 or fill out the form

Yes. BURGEN sachet liquid packing machines are engineered to handle recyclable, biodegradable, and compostable films. Special sealing jaws, ultrasonic sealing options, and temperature adjustments ensure compatibility with eco-friendly laminates. While eco films may vary in barrier properties, we test each film to optimize sealing strength and shelf-life. This makes it possible to run sustainable honey sachet packing machines or eco sachet projects without compromising on performance.

👉 Book a material test: WhatsApp +86 183 4440 8617 or submit your form.

Sealing is critical for liquids. BURGEN liquid sachet packing machines feature independent lane temperature control, dual sealing systems, and cooling jaws for robust seals. For honey sachets and viscous products, reinforced pressure sealing and ultrasonic options ensure no leakage. Each machine is equipped with leak prevention measures to deliver smooth, tamper-proof sachets.

👉 Ask for sealing solutions: WhatsApp +86 183 4440 8617 or fill out the form.

BURGEN’s sachet liquid packing machines integrate tear notches, laser perforations, and micro-scoring to create easy-open features. Each lane is independently controlled, ensuring precision at high speed. Rounded corners and shaped sachets can also be customized for cosmetics and premium food brands.

👉 Explore custom options: WhatsApp +86 183 4440 8617 or fill in the form.

Daily maintenance includes cleaning contact parts and inspecting seals. Weekly, operators should check knives, perforation tools, pumps, and temperature stability. Monthly, calibration and preventive maintenance help maintain accuracy. For pharma and honey sachet packing machines, BURGEN offers CIP/SIP cleaning systems, making sanitation fast and compliant. Training, spare parts availability, and remote diagnostics further extend uptime.

👉 Request a maintenance checklist: WhatsApp +86 183 4440 8617 or fill in the form.

Contact us now for specs, pricing & video demo.