Why Liquid Stick Pack Packaging Machines Are Gaining Global Attention

Liquid stick pack packaging machines are becoming indispensable in today’s packaging industry. From food and beverage to pharmaceuticals, their ability to deliver single-dose, portable, and hygienic solutions has made them highly relevant in markets like the United States, Canada, Germany, Japan, South Korea, Brazil, and Mexico.

A liquid stick pack packaging machine not only ensures precision in filling but also guarantees consumer convenience — a combination that aligns perfectly with modern lifestyles.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

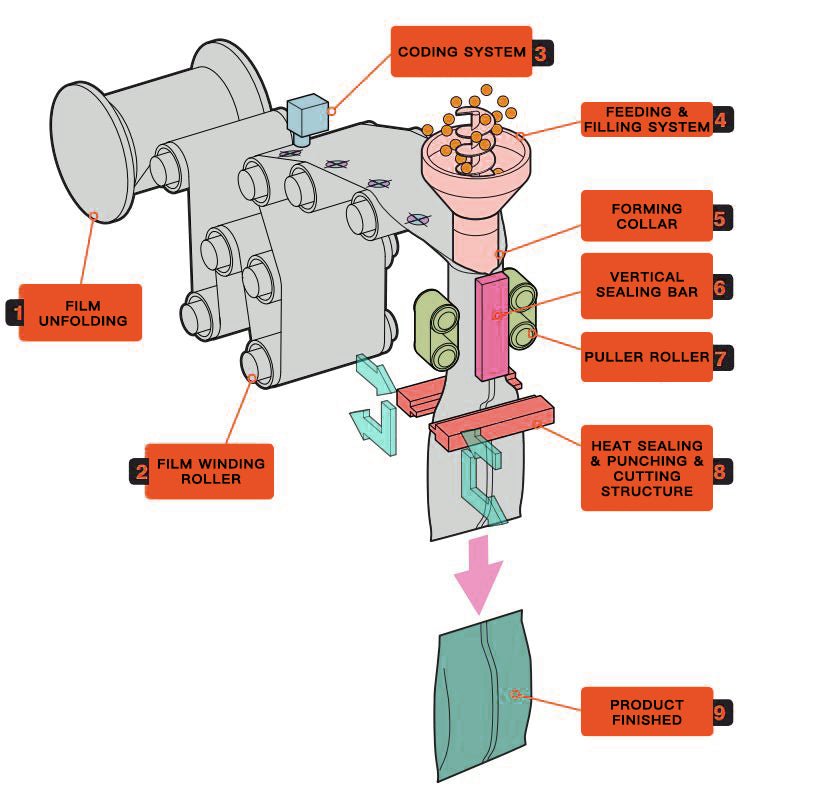

Technical Design & Working Principle

A liquid stick pack packaging machine is not just a filling unit, but a fully integrated high-precision system. Modern equipment incorporates several advanced design features:

Multiple Dosing Options: Depending on the product, machines can be equipped with pneumatic pumps, peristaltic pumps, or ceramic pumps. This flexibility ensures accurate filling for liquids of different viscosities — from isotonic energy gels to pharmaceutical syrups.

Independent Servo-Controlled Dosing: Each lane is equipped with its own servo motor, guaranteeing consistent dosing accuracy across multiple lanes. This is especially critical for high-precision applications such as ibuprofen liquid stick packs and pharmaceutical gels.

Quick-Release Cleaning Structure: The hopper assembly uses a fast-release design that reduces cleaning and changeover time from an industry average of one hour to just 20 minutes. This advantage allows nutraceutical factories to quickly switch between different flavors of liquid food supplement stick packs.

Enhanced Sealing Performance: Independent vertical sealing combined with secondary heat sealing ensures airtight packaging. This minimizes leakage risks for viscous products like honey stick packs and ketchup stick packs, while also improving pouch appearance.

High-Precision Forming Units: Unlike conventional sheet-metal parts, advanced models adopt German aluminum die-cast forming devices. The smoother surface reduces film scratching, misalignment, and wrinkling, ensuring stable pouch quality.

Independent Cutting Blades: Each lane is equipped with a precision blade manufactured using wire-cutting technology. This guarantees smooth edges and allows single-blade replacement, minimizing downtime and maintenance costs.

Optional Configurations: Built-in air tanks, static elimination systems, cooling for forming parts (water or air), and servo film correction can be added to further improve high-speed stability.

With these design features, liquid stick pack machines achieve both high output and consistent packaging quality, making them suitable for food, pharmaceutical, and nutraceutical applications.

Applications Across Industries

Food & Beverage

Ketchup stick pack packaging machines – convenient for quick-serve restaurants and take-out chains.

Lemon juice stick pack packaging machines – rising in European markets for cocktails and functional drinks.

Oil stick pack packaging machines – popular in Japan and Korea where single-serve edible oils are in demand.

Honey stick packing machine – widely adopted in North America for natural sweetener brands.

Nutritional Supplements

- Isotonic energy gel stick pack packaging machines – critical for sports nutrition in the U.S. and Brazil.

- Liquid food supplement stick pack packaging machines – popular among nutraceutical brands in Germany and the Netherlands.

Pharmaceuticals & Healthcare

Ibuprofen liquid stick pack packaging machines – precise dosing for pain relief products.

Pharmaceutical liquid stick pack packaging machines – compliant packaging for oral solutions.

Pharmaceutical gel stick pack packaging machines – effective for topical or oral gels.

Industrial & Others

- Silica gel stick pack packaging machines – for desiccants in electronics and pharmaceuticals.

- Sauces stick pack packaging machines – used by global food processors expanding in Latin America.

Key Advantages of Liquid Stick Pack Packaging Machines

Consumer convenience: single-serve, portable, easy to open.

Extended shelf life: airtight sealing ensures product stability.

Flexibility: handles a wide range of viscosities, from honey to isotonic gels.

Efficiency: automation reduces labor and improves throughput.

For buyers comparing equipment, our stick packing machine category offers a complete portfolio covering different viscosities and production scales.

Market Trends & Future Development

According to Euromonitor, single-dose packaging in functional beverages and nutraceuticals is projected to grow by over 8% annually in North America and Europe. In Asia-Pacific markets like Japan and Korea, demand for oil stick packs and lemon juice stick packs is expanding due to convenience-driven consumption.

For a deeper understanding of stick pack technology, see our comprehensive guide.

Choosing the Right Liquid Stick Pack Packaging Machine

When selecting equipment, companies should evaluate:

Viscosity of the liquid (water-like vs honey-like).

Required output (from 30 sticks/min to 500+ sticks/min).

Compliance standards (food-grade or pharmaceutical-grade).

After-sales and customization offered by the manufacturer.

In short

Liquid stick pack packaging machines are transforming the way industries deliver products, from ketchup and honey to ibuprofen solutions and energy gels. Their versatility, efficiency, and consumer appeal make them an essential investment for global brands.

2 Comments

bookmarked!!, I really like your site!

thx