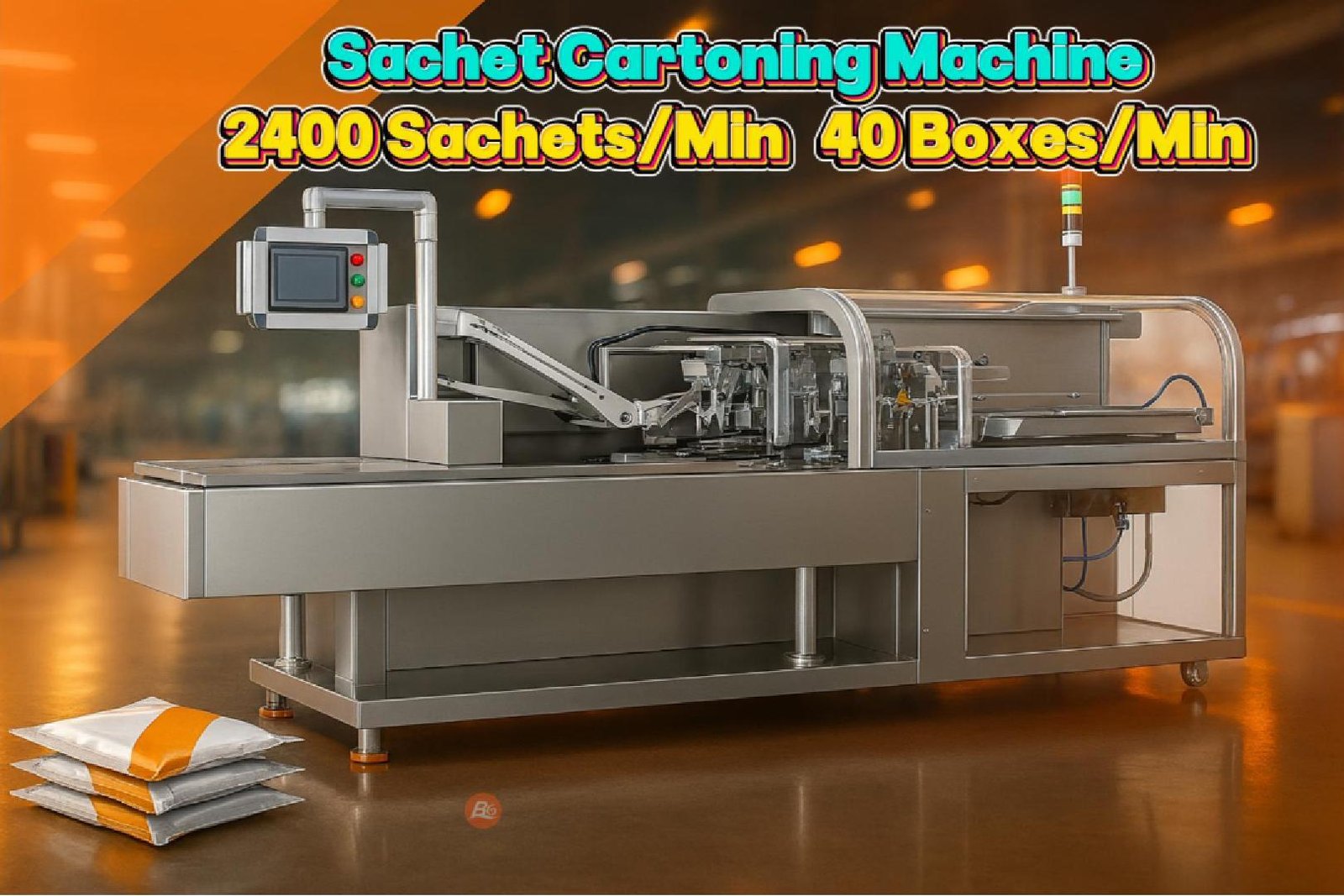

In today’s fast-moving consumer goods market, production managers are under constant pressure. You’re tasked with increasing throughput, minimizing downtime, and controlling costs, all while adapting to ever-changing product demands. One of the biggest trends driving this complexity is the rise of sachet packaging. From single-serve coffee to pharmaceutical powders and cosmetic samples, consumers love the convenience of sachets, and it’s up to you to package them efficiently. This is where a modern

sachet cartoning machine becomes more than just a piece of equipment—it becomes the core of your secondary packaging solution. At Burgen Machine, we understand that choosing the right machinery is a critical business decision that impacts your entire operation.

Meeting Diverse Industry Demands with a Single, Flexible Solution

The need for efficient sachet packaging spans multiple industries, each with its own unique and stringent requirements. A truly versatile cartoning machine must be engineered to meet these diverse challenges head-on.

For the Food & Beverage Sector

When packaging products like instant coffee, spices, or powdered drinks, hygiene and speed are non-negotiable. A reliable food cartoning machine must be designed for easy cleaning to meet food safety standards like NSF/ANSI, with smooth surfaces and no “dead corners” where residue can accumulate. At the same time, it must maintain high output to keep pace with demanding production schedules.

For the Pharmaceutical Industry

Precision, compliance, and traceability are paramount. A pharmaceutical cartoning machine must be built according to strict Good Manufacturing Practice (GMP) guidelines. This means using specific, non-reactive materials for all product-contact parts and ensuring flawless handling of sensitive products. Whether you need an ointment cartoning machine for single-dose applications or a system for packing powdered medicine sachets, the equipment must guarantee accuracy and gentle handling to protect product integrity.

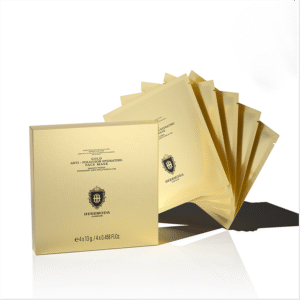

For the Cosmetics Market

This industry thrives on variety, promotions, and presentation. Packaging for products like facial masks or skincare samples often changes with marketing campaigns. Therefore, a machine like a facial mask cartoning machine needs to be incredibly flexible, allowing for quick, tool-free changeovers between different carton sizes and sachet counts. To explore solutions specifically designed for this dynamic sector, you can view our range of cosmetic packaging equipment here:

What Production Managers Really Need: Key Features That Drive ROI

While technical specifications are important, an experienced production manager knows that a machine’s true value is measured by its performance on the factory floor. The right investment addresses your biggest pain points and delivers a clear return.

The core of any efficient production line is a high speed cartoning machine that is, above all, reliable. Unplanned downtime is the number one enemy of productivity, costing you money and delaying shipments. That’s why robust construction, the use of world-class components from brands like Siemens, and a proven track record of uptime are critical decision factors.

Furthermore, with a global shortage of skilled labor, ease of use is no longer a luxury—it’s a necessity. A machine with an intuitive, multilingual HMI (Human-Machine Interface) and a design that allows for rapid changeovers dramatically reduces training time and empowers your existing team to operate it efficiently. This focus on operational excellence is at the heart of our premier—— sachet cartoning machine.

Choosing a Partner, Not Just a Machine

Investing in a cartoning machine is a long-term commitment that extends far beyond the initial purchase. The quality of the after-sales support you receive is just as important as the quality of the machine itself. This is especially true when sourcing equipment internationally.

A trustworthy supplier acts as a true partner, offering transparency, comprehensive documentation, and robust support. Key indicators of a reliable partner include :

Responsive Technical Support: A dedicated team of engineers available to help you troubleshoot issues remotely and minimize downtime.

Readily Available Spare Parts: A well-managed inventory of critical components that can be shipped quickly to your location.

A Commitment to Your Success: A willingness to understand your unique challenges and work with you to ensure the machine delivers optimal performance for years to come.

At Burgen Machine, we have built our reputation on being that reliable partner for businesses worldwide. We invite you to explore our full range of cartoning machines and see how our commitment to quality and support sets us apart.

Ready to solve your packaging challenges and boost your production efficiency? Contact us today to speak with one of our specialists and find the perfect solution for your needs.