Designed for beverages, sauces, and liquid detergents, our multi-head spout pouch filling machine delivers up to 5,000 pouches per hour with a filling accuracy of ±1%. Integrated CIP (Clean-in-Place) systems and Servo-driven capping keep your production hygienic and leak-proof, while modular components minimize downtime. Automate your line for consistent, high-quality output and maximize ROI.

Multi-Head High-Speed Filling Enables up to 5,000 pouches per hour to meet large-scale production demands efficiently.

±1% High-Precision Dosing Ensures consistent filling volume across every pouch, minimizing product waste and ensuring compliance.

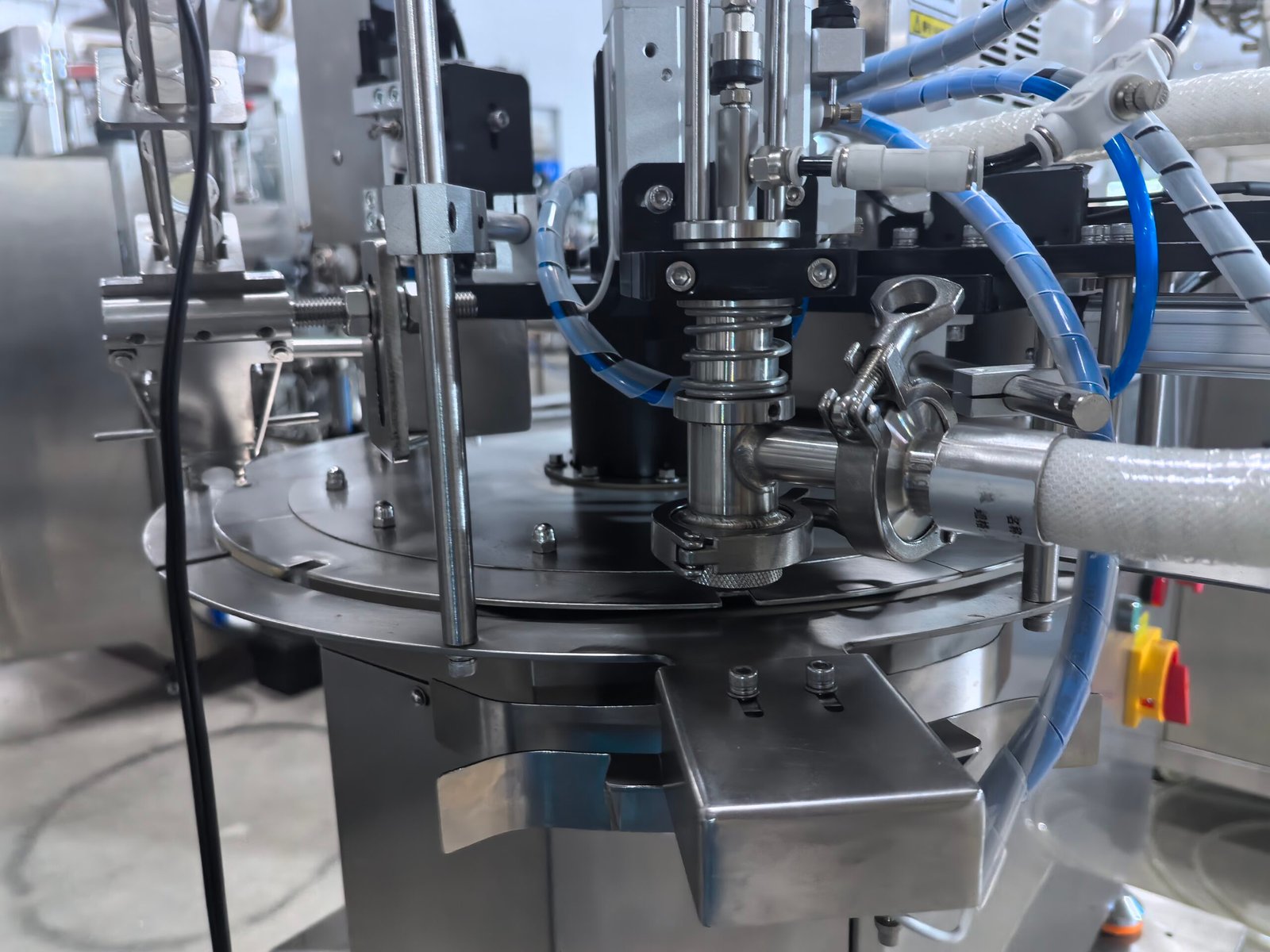

Servo-Driven Capping System Precision torque control ensures every cap is sealed perfectly to prevent leaks during transportation.

> 99% Uptime Reliability Simplified mechanical structure and high-quality components prevent unplanned stops and reduce maintenance.

Our advanced piston filling system is engineered specifically for liquids and pastes of varying viscosities, ensuring a clean and waste-free production environment.

Vacuum Suction Back-pull: Effectively eliminates dripping after filling to keep the spout threads clean.

±1% Filling Accuracy: High-precision servo motors ensure consistent volume across every single pouch.

Customizable Nozzles: Interchangeable filling heads to match different spout diameters and product types.

Hygiene is paramount. Our machine features a fully integrated cleaning system that allows for thorough sanitization without the need for manual disassembly.

Automated Cleaning Cycle: Simplifies the switch between different products (e.g., from juice to dairy).

360° Internal Flushing: High-pressure spray balls ensure no residue is left in the tanks or pipes.

Food-Grade Construction: All contact parts are made of SUS316L stainless steel for maximum corrosion resistance.

Achieve the perfect seal every time with our high-torque servo capping system, designed to prevent leaks and protect cap integrity.

Adjustable Torque Control: Precise digital settings via the PLC prevent over-tightening or loose caps.

Magnetic Clutch Technology: Ensures smooth engagement and prevents damage to the plastic threads.

Real-time Cap Detection: Automatically rejects pouches with missing or tilted caps.

Maximize efficiency and minimize product loss with our intelligent sensing array that monitors the status of every pouch on the line.

Zero Waste Guarantee: The filling nozzle will not activate if no pouch is detected at the station.

Auto-Stop Safety: The machine pauses and alerts the operator if a pouch jam or shortage occurs.

Seamless PLC Integration: Real-time data feedback to the main control screen for instant troubleshooting.

Whether you need to fill high-volume industrial containers, run high-speed spout pouch lines, or package in diverse premade pouch formats, our liquid packaging portfolio delivers hygiene, precision, and flexibility. Explore the right solution for your production scale and format.

Designed for high-volume demand, this machine automates the entire process from pouch feeding and vacuuming to precise liquid dosing and servo-capping. It is ideal for large-scale production of juice, dairy products, and liquid detergents.

Designed for stand-up, zipper and spout pouches with quick changeovers and precise dosing—perfect for retail-ready, consumer-friendly packaging.

A complete solution for rigid containers, integrating bottle washing, volumetric filling, capping, and labeling. It handles condiments, oils, and chemical liquids at high speeds with a filling accuracy of ±1%.

Hear directly from our clients in the food, beverage, and personal care sectors about how the BURGEN Spout Pouch Filling Machine optimized their liquid packaging lines, ensured leak-proof seals, and maximized production efficiency.

Since switching to the BURGEN rotary spout pouch filler for our fruit purees, our daily throughput increased by 35%. More importantly, the servo-driven capping has completely eliminated leakage issues during transit, securing our brand reputation.

material waste dropped

The ±1% filling accuracy is crucial for our high-value cosmetic lotions, significantly reducing product giveaway. We calculate that precise dosing alone saves us thousands in material costs every month compared to our old equipment.

Saved in Operational Costs

We run multiple SKUs daily. The tool-less quick changeover system allows us to switch between pouch sizes in under 20 minutes. Combined with the automatic CIP cleaning feature, our hygiene audits are now effortless.

Downtime has been reduced

Here are six of the most common questions about our powder stick packing machine—answered to help you make an informed decision.

We offer a 12-month comprehensive warranty covering parts and labor, plus an optional extended service plan.

Our technical support team responds within 24 hours, and on-site service is arranged within 72 hours of request.

Yes—local spare-parts warehouses in the US, EU, and Asia ensure most parts ship within 48 hours.

Absolutely—certified engineers handle installation, commissioning, and operator training at your facility.

Our machine is CE-marked, FDA-compliant (21 CFR), GMP-certified, and built under ISO 9001 quality standards.

We offer IoT-enabled remote monitoring, predictive maintenance alerts, and annual maintenance contracts to maximize uptime.