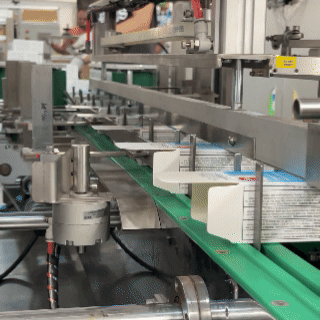

Our state-of-the-art cartoning line is engineered for cosmetic brands that demand speed, precision, and aesthetic perfection. Enjoy seamless integration, rapid changeovers, and compliance with global standards—so you can accelerate time-to-market without compromising on product beauty.

🚀 Exceptional Speed: Up to 300 cartons/min to meet high-volume production.

🤖 Effortless Automation: Tool-free changeovers in 5–10 minutes with digital recipe memory.

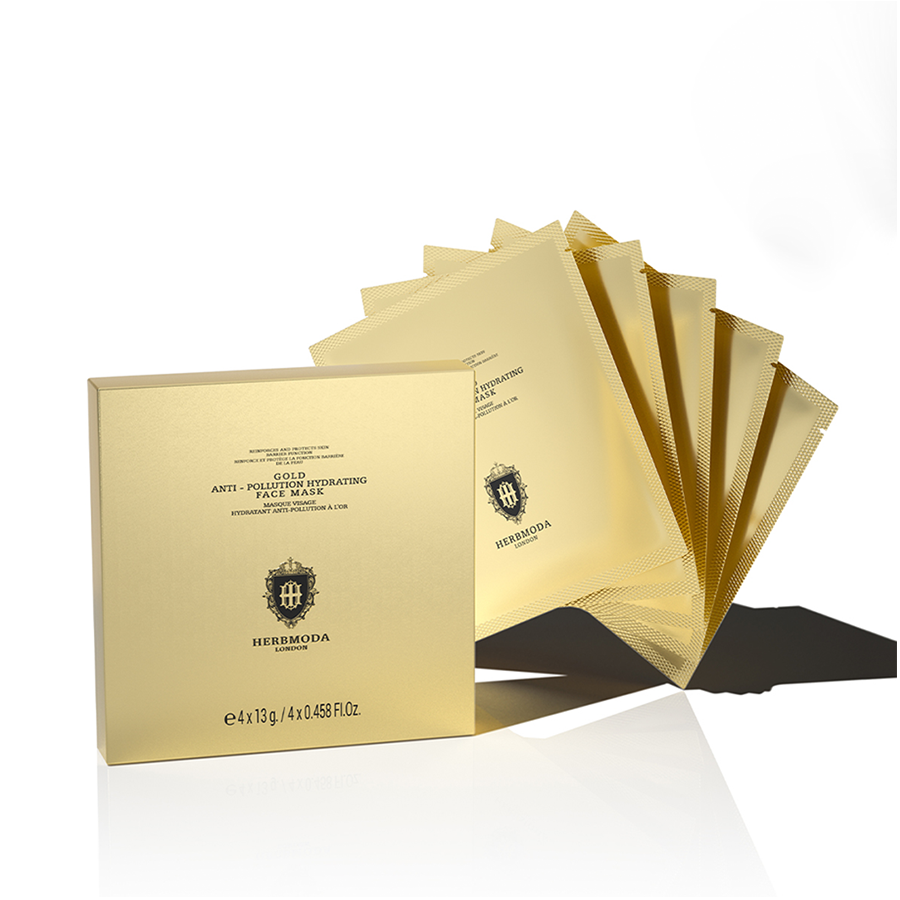

🎨 Flawless Finish: ±0.1 mm servo accuracy for scratch-free, mirror-like cartons.

📐 Compact Footprint: ≤ 2.5 m² space requirement, easily integrates with filling, labeling, and inspection lines.

🔒 Global Compliance & Support: ISO 22716, cGMP, CE, FDA certified, plus 24/7 remote diagnostics.

Experience the power of 300 cartons/minute, precision servo control, and tool-free changeovers in our quick demo. See how seamless integration and flawless packaging quality can elevate your beauty production line.

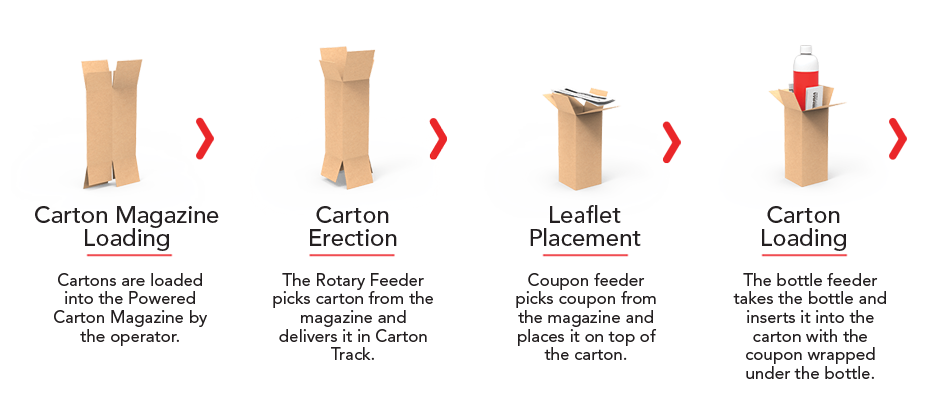

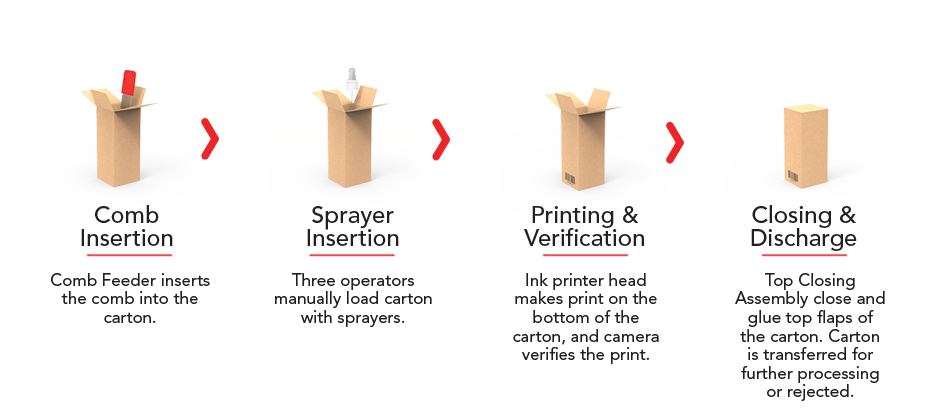

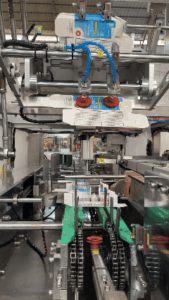

Automatically pick and erect flat cartons from the magazine.

High-Capacity Magazine: Holds up to 2,000 cartons for non-stop operation.

Servo-Driven Precision: Ensures every carton is erect in ±0.5 mm accuracy.

Hands-Free Feeding: Reduces manual intervention and speeds up startup.

Products are conveyed and gently inserted into the erected cartons.

Gentle Handling: Soft-belt conveyor minimizes scratches on delicate cosmetics.

Multi-SKU Flexibility: Accommodates different product shapes without tool changes.

High-Speed Insertion: Up to 300 cartons/min with zero mis-feeds.

Top and bottom flaps are folded and sealed automatically.

Dual Sealing Modes: Hot-melt glue or tuck-in, selectable per carton style.

Consistent Seal Quality: ±1 mm flap alignment for perfect closures.

Rapid Glue Cycle: Complete seal in under 1 second per carton.

Finished cartons exit onto the outfeed conveyor and pass through inspection.

Inline Vision Check: Detects missing products, mis-seals, and surface defects.

Auto Rejection: Defective cartons are removed without halting production.

Sync-Ready Outfeed: Easily integrates with secondary packing or palletizing.

Pair your cosmetic cartoning line with these high-performance feeders and packers to create a truly continuous, end-to-end packaging solution. Each machine syncs perfectly with our cartoner—no extra engineering required.

A servo-driven, multi-head volumetric pump capable of accurately dispensing lotions, creams, and gels at up to 200 fills/min. Hygienic 316L stainless-steel design with CIP/SIP support ensures fast cleaning, while built-in SMEMA interface lets it hand off filled containers directly to your cartoner.

Rapidly form, fill, and seal single-serve liquid stick packs at 120–150 sticks/min. PLC-controlled recipe management allows instant product changeovers in under 5 minutes, and its integrated conveyor seamlessly delivers finished sticks into the cartoning machine’s infeed station

Precision screw-feeding and multi-lane dosing handle powders from 0.5 g to 50 g per stick at speeds up to 100 sticks/min. Fully enclosed design minimizes dust, and the machine’s outfeed conveyor dovetails directly into the cartoner’s magazine loader for zero-gap production.

Hear directly from our clients in the food, pharmaceutical, and chemical sectors about how the Powder Sachet Packing Machine improved their throughput, ensured consistent product quality, and minimized material waste.

Since integrating the BURGEN Cosmetic Cartoning Machine, our line speed jumped by 35% and changeover time dropped from 20 minutes to just 7 minutes. The flawless carton finish has elevated our brand image, and remote diagnostics have cut downtime by 30%.

cut downtime

We needed precision and flexibility for multiple lipstick SKUs—BURGEN delivered. Our throughput increased from 180 to 260 cartons/min, and we’ve nearly eliminated mis-seals. Maintenance is a breeze, thanks to its digital recipe memory.

Saved in Operational Costs

The compact footprint fit perfectly into our limited cleanroom space. With ±0.1 mm accuracy, every box is mirror-smooth. Overall equipment effectiveness improved by 28%, and our ROI payback period shortened to under 14 months.

effectiveness improved

Here are six of the most common questions about our powder stick packing machine—answered to help you make an informed decision.

Our cartoner supports straight-tuck, reverse-tuck, crash-lock, and custom styles from 50×30×20 mm up to 300×200×100 mm. Changeovers between sizes are fully digital and tool-free.

Thanks to our tool-free modular design and digital recipe memory, you can complete a full changeover in just 5–10 minutes—no manual adjustments needed.

Daily checks include belt tension, lubrication points, and sensor alignment. Weekly tasks cover deeper inspection of sealing heads and pneumatic fittings. Our remote diagnostics will alert you to any issues before they lead to downtime.

Yes—our cartoner features standard SMEMA and CIP interfaces, allowing plug-and-play connection to fillers, labelers, checkweighers, and more. No extra PLC coding required.

We are CE, cGMP, FDA (where applicable), and UL certified. The stainless-steel and anodized-aluminum construction also meets ISO 22716 cosmetic GMP guidelines.

Clients often see ROI within 12–18 months thanks to labor savings, reduced downtime, and higher throughput. Our TCO analysis includes parts, service, and energy consumption for a clear financial outlook.