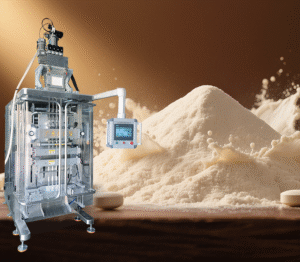

In the rapidly expanding market of single-serve beverages, selecting the right equipment is pivotal for business growth. For a medium-scale production line, the ideal automatic stick packing machine must strike a delicate balance between high-speed output and consistent dosing accuracy. Whether you are packaging free-flowing granules or complex powder mixes, the machine you choose defines your production efficiency and product quality.

Dosing Systems: Adapting to Powder Characteristics

The most critical factor in selecting a machine is the nature of your raw material. White sugar stick pack packaging machines typically utilize volumetric cup fillers because sugar granules flow freely and consistently. This system offers high speed and reliability at a cost-effective price point. However, this method is often unsuitable for cohesive powders that can bridge or clump.

Conversely, for products like 3-in-1 instant coffee mix stick pack packaging machines, which contain a blend of coffee powder, creamer, and sugar, a servo-driven auger filler is superior. The auger screw provides positive displacement to handle the variable density of the mix, ensuring that every stick pack contains the precise weight and flavor profile intended. This level of control is essential for maintaining the premium reputation of your brand.

Scalability: The Power of Multi-Lane Configuration

For medium-scale operations, a single-lane machine often creates a bottleneck. To meet market demand efficiently, upgrading to a multi-lane coffee stick pack packaging machine is the strategic choice. These machines typically run between 4 to 12 lanes simultaneously, multiplying your output without significantly increasing the factory footprint.

When configuring your line, it is vital to assess the specific capabilities of Powder Stick Packing Machines. A robust multi-lane system ensures that even when running high-demand products like 2-in-1 instant coffee mix stick pack packaging machines, the seal integrity and weight accuracy remain consistent across all lanes. This stability prevents costly downtime and material waste, directly impacting your bottom line.

Sealing Technology: Preserving Freshness and Aroma

Coffee and drink powders are highly sensitive to moisture and oxygen. Therefore, ground coffee stick pack packaging machines require advanced sealing technologies to preserve the delicate aroma and freshness of the product. The best machines feature independent PID temperature controllers for both horizontal and vertical sealing jaws, ensuring an airtight hermetic seal suitable for multi-layer laminated films (e.g., PET/AL/PE).

Hygiene and Easy Maintenance

In food production, hygiene is non-negotiable. An optimal automatic stick packing machine should feature an open frame design crafted from SS304 stainless steel, allowing for easy cleaning and maintenance. This is particularly important when switching production runs, for example, from a strong coffee blend to a pure sugar product, where cross-contamination must be eliminated.

Manufacturers looking for the highest standards in hygiene often look toward our Nutraceutical Stick Pack Packaging Solution, as the rigorous sanitary design principles applied there are equally beneficial for high-quality food powder lines. Ensuring your equipment meets these standards builds long-term trust with international buyers and regulatory bodies.