In an era defined by convenience and on-the-go lifestyles, single-serve packaging has become more than a trend—it’s a necessity, a shift confirmed by top industry reports on beverage packaging trends from PMMI. At the forefront of this revolution is the stick packing machine, a highly efficient and versatile piece of equipment that has transformed how brands package their products. From your morning coffee to essential nutritional supplements, the compact and convenient stick pack is a direct result of this innovative technology.

A stick packing machine is an automated system designed to take a roll of flexible packaging film, form it into a narrow, tube-like pouch, fill it with a predetermined amount of product, and then seal it. The result is the sleek, portable “stick pack” that is now ubiquitous across numerous industries. This equipment is a cornerstone for businesses looking to enhance production speed, ensure product freshness, and appeal to the modern consumer.

How Does a Stick Packing Machine Operate?

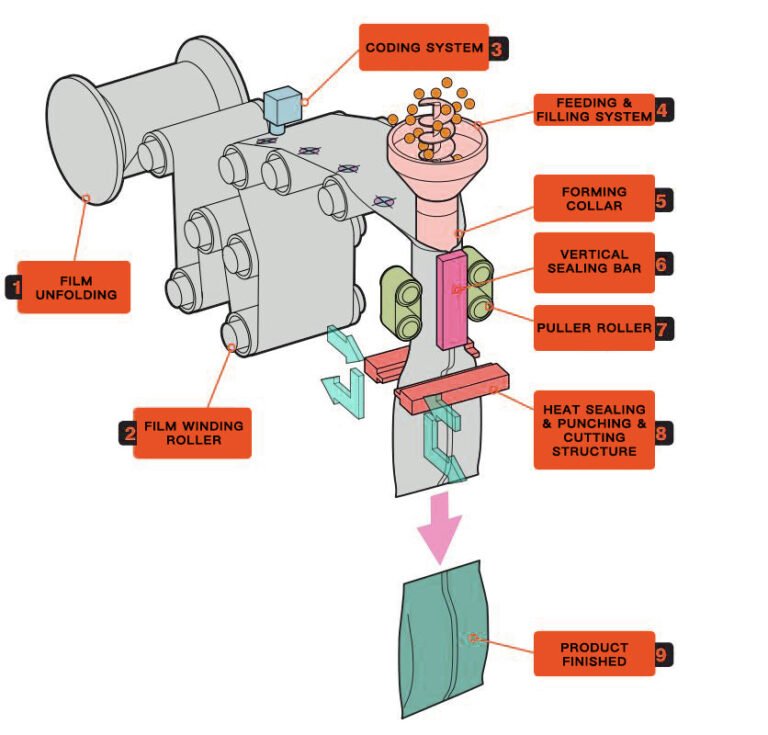

The process, while seemingly complex, is a marvel of engineering efficiency. A typical stick pack packaging machine follows a precise sequence:

Film Transport and Forming: The process begins with a large roll of packaging film being fed into the machine. The film is precisely split into multiple lanes and then passes through a forming tube assembly, which folds the flat film into the characteristic long, narrow stick shape.

Vertical Sealing: Once formed, the overlapped edges of the film are sealed together by heated vertical sealing bars. Advanced machines feature individual temperature controls for each lane, ensuring a strong, consistent vertical seam for every single pack.

Product Filling: This is arguably the most critical stage. Depending on the product, a specific type of filler is integrated. For powders, an auger filler dispenses a precise volume. For liquids and gels, a volumetric piston or liquid pump is used. This precision is vital for everything from pharmaceuticals to food products.

Horizontal Sealing and Cutting: After filling, heated horizontal sealing jaws clamp down on the tube to create the top seal of one stick and the bottom seal of the next. A knife within this assembly then cuts the filled stick pack, separating it from the line.

Discharge: The finished stick packs are then discharged from the machine, often onto a conveyor belt for secondary packaging, such as cartoning or counting.

The Power of Multi-Lane Production: Scaling Your Output

A defining feature of the modern stick packing machine is its multi-lane capability. Unlike single-pouch machines, a multi-lane system is designed to produce multiple stick packs simultaneously in parallel rows, or “lanes.” This is the key to achieving the high production volumes required by commercial operations.

These machines can be configured with anywhere from two to twenty or more lanes. The number of lanes is directly proportional to the machine’s output. For example, if a machine operates at a speed of 50 cycles per minute:

A 4-lane machine will produce 200 stick packs per minute.

A 10-lane machine will produce 500 stick packs per minute.

A 20-lane machine can achieve an impressive 1,000 stick packs per minute.

Each lane functions as a semi-independent production line, with its own dedicated forming tube, filling nozzle, and sealing components. However, they are all synchronized to a central drive system, ensuring that the forming, filling, sealing, and cutting actions occur in perfect harmony across all lanes. The choice of how many lanes to implement depends on a company’s specific production goals, the width of the stick pack, and the available factory floor space. This scalability is what allows a stick packing machine to grow with a business, from a small startup to a large-scale industrial producer.

Diverse Applications Across Industries

The adaptability of the stick packing machine is its greatest asset, making it indispensable for a wide range of products.

In the bustling food and beverage sector, these machines are paramount. The demand for convenience has led to the widespread use of 2-in-1 instant coffee mix stick pack packaging machines and their even more popular counterparts, the 3-in-1 instant coffee mix stick pack packaging machines. These systems expertly handle the delicate, free-flowing powders. For athletes and fitness enthusiasts, the isotonic energy gel stick pack packaging machines provide a reliable method for packaging viscous liquids.

The pharmaceutical and nutraceutical industries also rely heavily on this technology. The accuracy and sanitation offered by food supplement powder stick pack packaging machines are critical for delivering precise doses of vitamins and health products, all while adhering to strict safety standards like the FDA’s regulations for food contact substances.

Beyond consumables, the industrial applications are just as important. For instance, silica gel stick pack packaging machines are used to create the small desiccant packs that protect goods from moisture damage.

Why Invest in a Stick Packing Machine?

The benefits extend far beyond simple packaging. A modern stick packing machine offers a significant return on investment through:

Material Savings: Stick packs use significantly less packaging material compared to traditional 4-sided seal sachets.

Enhanced Efficiency: Multi-lane machines can produce hundreds of stick packs per minute, drastically increasing output.

Consumer Convenience: They are easy to open, easy to carry, and provide a perfect single serving.

Brand Appeal: The sleek design offers a premium look and feel.

Product Integrity: The secure seals protect the product from contaminants, extending shelf life and ensuring dose accuracy.

In conclusion, the stick packing machine is a cornerstone of modern automated packaging. Its ability to handle diverse products while offering unparalleled efficiency makes it a vital asset. If you are looking to thrive in the competitive single-serve market, the right stick pack packaging machine can elevate your production line and your brand.

1 Comment

[…] For a deeper understanding of stick pack technology, see our comprehensive guide. […]