Selecting the right packaging equipment depends on production goals and specific product needs. Manufacturers seeking flexibility, easy changeovers, and artisanal packaging often prefer a premade pouch packing machine. Those prioritizing high-speed output and efficiency for large-volume runs typically choose form fill seal machines. Key decision factors include cost, speed, flexibility, packaging quality, maintenance, and product suitability. A recent industry analysis shows vertical pouch machines leading their segment, while form fill seal machines dominate continuous, high-speed packaging. Each business should match machine strengths with its unique requirements.

What Is a Premade Pouch Packing Machine?

A premade pouch packing machine automates the process of packaging products into pre-formed pouches. This equipment picks up empty pouches, opens them, fills them with product, and seals them securely. Manufacturers use these machines to improve efficiency and maintain consistent packaging quality. The system adapts to a wide range of pouch types and product forms, including solids, powders, liquids, and granules.

Primary Functions:

- Automated picking, opening, filling, and sealing of premade pouches.

- Consistent packaging quality and improved production efficiency.

- Adaptability to various pouch types and product forms.

Typical Applications:

- Food industry: snacks, nuts, dairy, and juices.

- Pharmaceuticals: granulated medicines, capsules, and medical devices.

- Agriculture: seeds, fertilizers, and pesticide granules.

- Pet food: dry and wet pet food, treats.

- Chemicals: pigments and additives.

Supported Pouch Types:

- Stand-up, zipper, flat bottom, three-side seal, four-side seal, and custom-shaped pouches.

A premade pouch packing machine offers high automation, reduces manual labor, and delivers stable, reliable packaging. Companies benefit from enhanced product presentation, flexibility in handling different pouch sizes, and reduced packaging material waste.

Tip: Businesses seeking premium branding and flexibility often choose premade pouch packing machines for their ability to handle diverse pouch styles and product types.

What Is a Form Fill Seal Machine?

Form fill seal machines create packages from flat film or packaging material, fill them with product, and seal them—all in one continuous process. These machines operate in three main steps:

Form: The machine shapes the package from a roll of film or existing material.

Fill: It dispenses a pre-measured amount of product into the formed package.

Seal: The package is sealed immediately after filling.

There are two main types:

Vertical form fill seal (VFFS) machines, which form packages vertically and suit products like grains, liquids, and chips.

Horizontal form fill seal (HFFS) machines, which form packages horizontally and work well for items such as candy bars or toys.

Form fill seal machines package foods, liquids, powders, and standalone products. They offer high-speed operation, versatility, and cost-effectiveness by automating the entire packaging process.

Key Differences

Cost

Cost remains a primary consideration when selecting between a premade pouch packing machine and a form fill seal machine. The initial investment for both types can vary based on automation level and capacity. However, ongoing operational costs often differ more significantly.

Premade Pouch Packing Machines | Form Fill Seal Machines | |

|---|---|---|

Changeover Cost | Higher due to need for new pouch inventory | Lower by adjusting film settings |

Maintenance | More complex, implying higher ongoing costs | Simpler design, potentially lower maintenance costs |

A premade pouch packing machine typically incurs higher ongoing costs. The pouches themselves cost more because of their complex production process. Maintenance also tends to be more involved, which can increase after-sales expenses. In contrast, form fill seal machines use film rolls, which are less expensive and easier to store. Their simpler design often results in lower maintenance costs, making them attractive for startups or businesses with limited budgets.

Additional cost factors include energy consumption and spare parts. More efficient machines save money over time. Replacement of wear parts usually accounts for 1-3% of the machine’s initial price per year. Preventive maintenance and emergency support are necessary for both, but the complexity of a premade pouch packing machine may lead to higher service costs.

Note: Simpler machine designs, such as those found in form fill seal machines, can help reduce maintenance and support expenses.

Speed

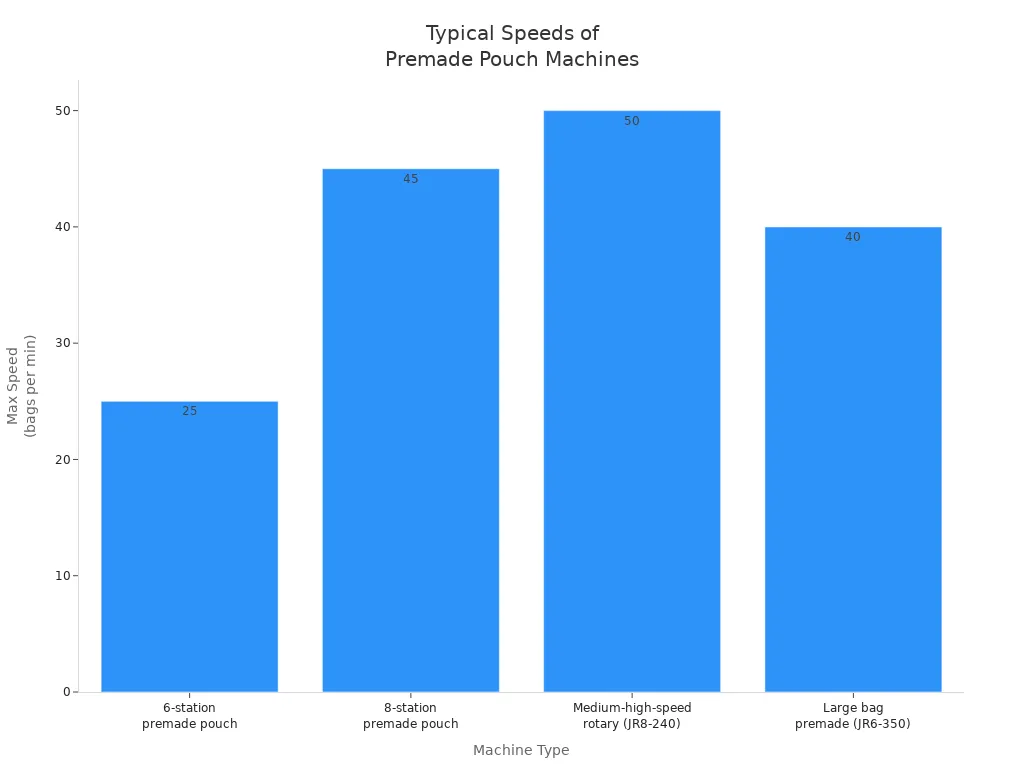

Speed directly impacts production efficiency, especially in high-volume environments. The packaging speed of each machine type varies by configuration and product.

Machine Type / Configuration | Typical Speed (bags per minute) | Notes |

|---|---|---|

6-station premade pouch machine | Around 12 to 25 bpm | Speed influenced by product characteristics and filling equipment |

8-station premade pouch machine | Around 25 to 45 bpm | Highest stable speed for typical 8-station machines |

Medium-high-speed rotary premade pouch machine (JR8-240) | Up to 50 bpm (approx. 3000 bags per hour) | Speed depends on product and filling weight |

Large bag premade pouch machine (JR6-350) | Up to 40 bpm (approx. 2400 bags per hour) | Designed for large bags, speed varies with product |

The Viking 8SQ-135, a high-speed rotary premade pouch packing machine, can reach up to 200 bags per minute by filling four bags simultaneously. This demonstrates the potential for rapid output, though most models operate at lower speeds.

Form fill seal machines generally achieve higher speeds, sometimes exceeding 100 pouches per minute, making them ideal for large-scale production. High-speed machines help manufacturers meet production deadlines and maintain throughput. Advanced automation reduces downtime, supporting continuous operation and maximizing efficiency.

Speed and efficiency are crucial for meeting production targets.

High-speed machines support large-volume packaging environments.

Balancing speed with packaging quality ensures product integrity.

Flexibility

Flexibility refers to how easily a machine adapts to different packaging formats, product types, and production changes.

Aspect | Premade Pouch Packing Machines | Form Fill Seal (FFS) Machines |

|---|---|---|

Packaging Formats | Use preformed bags such as doy packs, gusset bags, pillow pouches, and four-side seal pouches. Supports various materials and opening types (e.g., zippers, tear notches). | Form pouches from flat film rolls, allowing more customization in pouch sizes and styles. |

Product Types | Suitable for powders, liquids, pet food, food items, pharmaceuticals, cosmetics, snacks, dried fruits. | Also suitable for many products but with greater flexibility in pouch design. |

Operation & Changeover | Faster setup and simpler operation; quick changeover by switching pre-made bags. | More complex operation as pouches are formed, filled, and sealed in one process. |

Production Speed | Moderate speed (e.g., 35-60 pouches per minute). | Higher speed (e.g., up to 100 pouches per minute). |

Space Requirements | Requires more storage space for preformed pouches. | More compact; less storage needed as pouches are formed on demand. |

Flexibility in Packaging | Limited to available pre-made pouch sizes and styles. | Greater flexibility in pouch formation and customization. |

A premade pouch packing machine offers quick and easy changeovers, making it suitable for frequent product changes and short production runs. Touchscreen controls simplify adjustments, allowing operators to switch between pouch sizes or products rapidly. This flexibility benefits businesses with multiple SKUs or seasonal products.

Form fill seal machines provide greater customization in pouch size and style because they form pouches from rollstock. However, changeovers take longer and require more technical expertise. These machines work best for long runs with fewer product changes.

Doy packs, gusset bags, pillow pouches, and four-side seal pouches are common with premade pouch packing machines.

Form fill seal machines allow for more pouch customization and on-demand formation.

Packaging Quality

Packaging quality includes seal integrity, appearance, and consistency. A premade pouch packing machine uses pouches formed off-site, ensuring uniformity and premium appearance.

Fully automated operation ensures high efficiency and low labor input.

Premade pouches provide strong seal integrity and consistent appearance.

Supports various pouch formats with quick size changeover.

Hygienic design with food-grade stainless steel maintains product safety.

Intelligent controls prevent filling without a pouch, reducing waste.

Premade pouch packing machines deliver superior packaging quality due to the consistency of pre-formed pouches. These pouches often feature high-quality, pre-printed designs that enhance shelf appeal and branding. Reduced material waste occurs because the pouches arrive ready for filling and sealing.

Form fill seal machines may generate more material waste during pouch formation. They require more setup and adjustments, which can affect consistency. While they offer flexibility in pouch design, the appearance and seal quality may not always match the uniformity of premade pouches.

Maintenance

Maintenance affects machine uptime and production schedules. Both machine types require regular inspections, lubrication, and part replacements.

Machine downtime for maintenance halts production, causing lost productivity.

Planned preventive maintenance reduces unexpected failures and stabilizes production.

Unplanned breakdowns disrupt schedules and increase costs.

Understanding wear patterns and scheduling maintenance improves reliability.

A premade pouch packing machine often involves more complex maintenance due to its intricate mechanisms. This can lead to higher costs and longer downtimes if not managed properly. Form fill seal machines, with their simpler design, usually require less maintenance and experience shorter downtimes. Preventive maintenance increases machine lifespan and reduces the risk of unplanned breakdowns for both types.

Product Suitability

Product characteristics such as viscosity, particulate size, and fragility influence machine selection.

Machine Type | Packaging Characteristics and Advantages | |

|---|---|---|

Premade pouch packing machines | Products needing diverse, pre-formed, visually appealing packaging | Uses pre-formed bags (stand-up, flat, zipper, nozzle, handle); higher bag cost; filling and sealing only |

Form Fill Seal (FFS) machines | Products requiring flexible pouch sizing and continuous packaging | Forms pouch from film; adjustable pouch size; two types: HFFS and VFFS |

HFFS (Horizontal FFS) | Candy, protein bars, baked goods, frozen foods, medical devices, irregular products (toys, parts) | Horizontal packaging; precise operation; larger footprint |

VFFS (Vertical FFS) | Free-flowing products like nuts, sugar, salt, liquids | Vertical packaging; smaller footprint; efficient for free-flowing items |

Premade pouch packing machines excel with products that require premium branding and a variety of pouch styles, such as snacks, pet food, pharmaceuticals, and cosmetics. They handle liquids, powders, granules, and solids with ease. Form fill seal machines suit high-volume, continuous packaging of products like grains, sugar, and liquids, especially when pouch size flexibility is important.

Viscosity determines the filling technology required.

Particulate size and fragility influence machine choice to prevent clogging or product damage.

Proper machine selection ensures product integrity and efficient packaging.

Premade Pouch Packing Machine Pros and Cons

Advantages

A premade pouch packing machine offers several operational and branding benefits for manufacturers. Industry experts highlight the following advantages:

High operational speed, with some models reaching up to 200 cycles per minute, supports efficient high-volume packaging.

Versatility in handling a wide range of pouch types, such as stand-up, flat, three-side, and four-side sealed pouches, as well as various product forms including liquids, powders, granules, and solids.

Advanced sealing technologies, like nitrogen flush and vacuum sealing, help preserve product freshness and extend shelf life.

Seamless integration with ERP and SCADA systems enhances operational control and consistency.

Automation reduces labor costs, increases accuracy, and ensures consistent packaging quality.

Powers, Inc. demonstrates how a premade pouch packing machine supports frequent product changeovers and multiple product types within a single shift. This flexibility allows businesses to meet niche market demands and maintain product freshness.

“The industry is in desperate need of automated manufacturing technologies that have the intelligence to adjust, size change, troubleshoot, and run themselves without the need for operators. We expect to lead the industry as we develop new high-speed VFFS and premade pouch machines, coupling them with new high-speed automated secondary packaging. All of this will be done with the customer in mind, with the goal of reducing the manual labor needed to meet or exceed current demands.” – Scott Miller, VP of Business Development

A premade pouch packing machine also enables innovative packaging designs and branding opportunities. Features like high precision, quick pouch type changes, and support for multiple pouch styles help brands stand out in the market.

Disadvantages

Despite their strengths, premade pouch packing machines present several challenges:

High initial investment costs can be a barrier for small and medium businesses.

Regular maintenance is necessary, leading to ongoing expenses and potential production interruptions.

Limited flexibility, as these machines only work with pre-made bags, restricts packaging design and size options.

Skilled technical operators are required for operation and maintenance.

Machines can be fragile and prone to breakdowns if not handled properly.

Quality control depends on precise calibration and maintenance, which can be demanding.

Disadvantage | Description | Impact on Efficiency |

|---|---|---|

Packaging Size Limitations | Bag size range restricted to height 120-400mm and width 10-300mm. | Limits product variety and may require manual handling. |

Feeding Method Complexity | Difficult to adapt feeding methods for new products. | Reduces adaptability and may cause operational delays. |

Maintenance Requirements | Requires timely maintenance for optimal service life. | Increases operational costs and risk of downtime. |

Machine Complexity | Complex to operate and maintain, especially rotary types. | Adds to operational challenges and potential downtime. |

Some pouch types, such as spout pouches, are vulnerable to punctures and tears. Recycling can be complicated due to multi-material construction, and customization options remain limited compared to other packaging formats.

Form Fill Seal Machine Pros and Cons

Advantages

Form fill seal (FFS) machines deliver significant benefits for manufacturers seeking efficiency and scalability. These machines automate the entire packaging process, which increases productivity and reduces labor costs by up to 30%. Companies can package a wide range of products, including granular, powdery, and liquid items, using various bag formats such as pillow bags, stand-up pouches, and back-seal bags.

Automation minimizes human error and speeds up packaging, supporting high-volume production environments.

High-speed operation, with some models reaching up to 300 bags per minute, meets demanding output requirements.

Precision filling technology ensures consistent product quality and reduces material waste.

Quick changeovers allow for fast adaptation to different products and packaging formats, enhancing production flexibility.

Robust construction and reliable sealing technology protect products and extend shelf life.

Vertical design saves valuable floor space, making these machines suitable for facilities with limited room.

Integration with upstream and downstream equipment, such as multihead weighers and conveyors, creates seamless automated production lines.

Eco-friendly features support sustainable packaging initiatives and help reduce waste emissions.

User testimonials highlight improvements in production efficiency of up to 40% and consistently high packaging quality, giving companies a competitive edge.

Disadvantages

Despite their strengths, form fill seal machines present several challenges that businesses must consider. The initial investment for vertical form fill seal (VFFS) machines often exceeds that of other packaging equipment. Operators require training to manage setup, film changeovers, and maintenance tasks effectively.

Frequent maintenance is necessary for certain components, which can lead to downtime if not scheduled properly.

These machines struggle with products that cannot contain trapped air, such as delicate or highly perishable items.

Handling liquids or products with variable density may prove difficult, limiting product suitability.

Fine, aerated powders or moist products needing breathable packaging are not ideal for FFS systems.

The machines work best with plastic films, which may not align with regulations targeting single-use plastics.

Cost-effectiveness depends on running single bag sizes and weights for extended periods, making short runs less practical.

Sealing limitations restrict the use of thinner or more varied materials, reducing packaging flexibility and product variety.

Reducing seal bar width or sealing time to increase speed can compromise package integrity, increasing the risk of leaks.

Note: While FFS machines offer flexibility in packaging styles, technical constraints in sealing and material compatibility can limit design options and product range.

Choosing the Right Machine

Decision Factors

Selecting the right packaging equipment requires careful evaluation of several core factors. Companies should match the machine to the physical characteristics of their products, such as whether they handle liquids, powders, or solids. Production speed must align with output goals. For example, a premade pouch packing machine offers quick changeovers and flexibility, making it ideal for businesses with multiple product lines or frequent packaging changes. Form fill seal machines suit high-volume, single-product runs due to their efficiency and lower material costs.

Business size also plays a key role. Smaller operations or those with annual volumes below one million units often benefit from the shorter payback period of premade pouch systems. Larger manufacturers with predictable, high-volume output may find form fill seal machines more cost-effective. Companies should also consider the available production space, ease of use, and maintenance requirements. Long-term performance and supplier support influence reliability and future scalability.

Tip: Partnering with a reliable supplier ensures access to technical support, spare parts, and ongoing service, which supports business growth and minimizes downtime.

Checklist

Use the following checklist to guide your decision-making process:

What is the primary product type (liquid, powder, granule, solid)?

Does the machine accommodate your required bag sizes and packaging volumes?

What level of automation fits your production needs (fully automatic or semi-automatic)?

Is the machine’s footprint compatible with your facility’s available space?

How easy is the machine to operate, clean, and maintain?

Does the equipment support the desired bag styles (stand-up, gusseted, pillow, etc.)?

What is the expected production speed, and does it match your output targets?

Are the packaging materials compatible with your product and branding requirements?

Can the machine scale or upgrade to meet future growth?

What after-sales support and service does the supplier provide?

Have you calculated the total cost of ownership, including purchase, installation, training, and maintenance?

Does the machine comply with industry quality and safety standards?

Checklist Item | Premade Pouch Packing Machine | Form Fill Seal Machine |

|---|---|---|

Product Variety | High flexibility for multiple SKUs | Best for single-product, long runs |

Changeover Speed | Fast and simple | Slower, more technical |

Operator Requirement | Full-time operator for pouch loading | Operator can multitask |

Scrap Handling | Minimal onsite scrap | Generates film scrap onsite |

Scalability | Modular, easy to upgrade | Scalable with smart upgrades |

Note: Always calculate return on investment and payback period to ensure your choice supports both current and future business goals.

FAQ

What products work best with premade pouch packing machines?

Premade pouch packing machines handle snacks, pet food, powders, liquids, and pharmaceuticals. They suit products that require premium packaging or frequent changeovers. Companies often choose these machines for items needing strong shelf appeal or multiple pouch styles.

How do form fill seal machines reduce packaging costs?

Form fill seal machines use rollstock film, which costs less than pre-formed pouches. These machines also minimize labor by automating forming, filling, and sealing. High-speed operation further lowers per-unit packaging costs.

Can one operator run both machine types?

One trained operator can manage either machine, but premade pouch packing machines often require more attention for pouch loading. Form fill seal machines allow operators to multitask because of their higher automation and continuous operation.

What maintenance tasks do these machines require?

Task | Premade Pouch Machine | Form Fill Seal Machine |

|---|---|---|

Lubrication | ✔️ | ✔️ |

Seal bar cleaning | ✔️ | ✔️ |

Sensor checks | ✔️ | ✔️ |

Film alignment | ❌ | ✔️ |

Regular cleaning, lubrication, and sensor checks keep both machines running smoothly. Form fill seal machines also need film alignment checks.

Are these machines suitable for eco-friendly packaging materials?

Many modern machines support recyclable or compostable films. However, material compatibility depends on sealing technology and film thickness. Companies should confirm with suppliers before switching to sustainable packaging.

2 Comments

Your comment is awaiting moderation.

[…] High Initial Investment […]

[…] machine pays for itself in about 13 months. Interestingly, smaller businesses with annual volumes under one million units often see a faster payback with premade pouch […]

Thank you for sharing your insights! We are glad you found the ROI analysis helpful. You’ve highlighted a critical point for growing brands: choosing between a Premade Pouch System and a Form-Fill-Seal (VFFS) System is not just about the initial cost, but about balancing production volume with operational flexibility.

At Burgen Machine, we specialize in helping businesses transition seamlessly as their volumes increase. Whether you are starting with premade pouches for premium shelf appeal or scaling up to high-speed automated lines, we provide the technical expertise to ensure your 13-month payback goal is met or even exceeded.

If you are looking for a specific configuration to optimize your loss-in-weight integration, we’d love to discuss a tailored solution. Please feel free to reach out via our contact page!